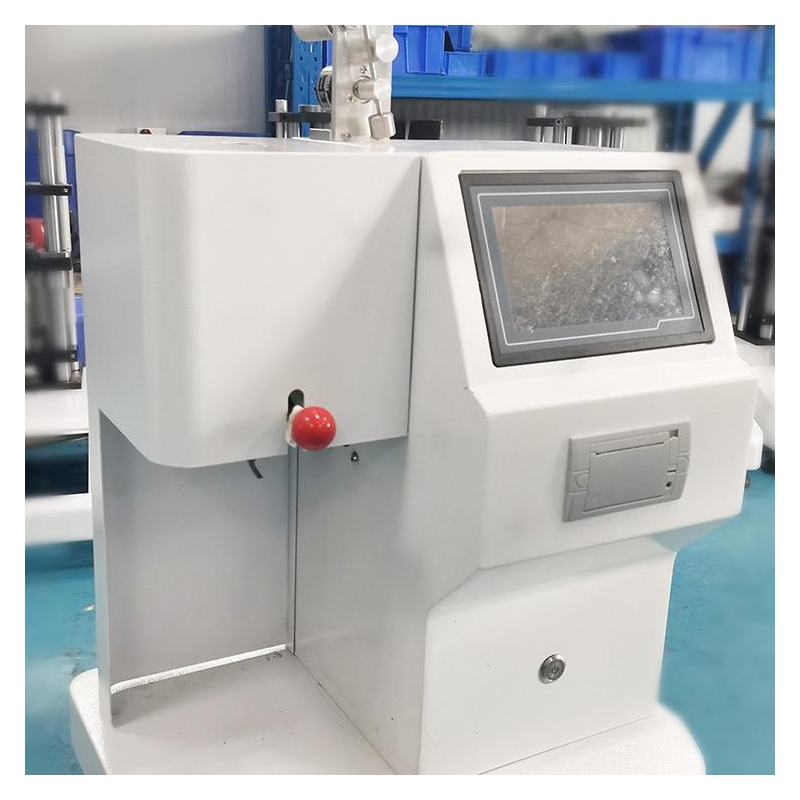

ZT-1010D PLC Type PP PE PVC Plastic Melt Flow Index Test Equipment MFI

Plastic Rubber Melt Flow Index Test Equipment

Specifications:

|

Temperature Range |

40℃-450℃ |

|

Temperature drift |

4hour, ≤0.5℃ |

|

Display Device |

Touch screen controlled |

|

Temperature fluctuation |

± 0.2℃ |

|

Temperature uniformity of 10mm-70mm above the die |

± 1℃ |

|

Temperature display resolution |

0.1℃ |

|

Time display resolution |

0.1S |

|

Cutting timing range |

1-999S adjustable |

|

Mouth mold diameter |

Φ2.095±0.005mm ( Mouth Radius : 1.05 mm + 0.005 ) |

|

Discharge hole length |

8.000 ± 0.025mm |

|

Piston rod diameter |

9.474 ± 0.007mm |

|

Piston rod length |

6.35 ± 0.13mm |

|

Loading container diameter |

Φ9.550 ± 0.007mm |

|

Test range |

0.1-150g / 10min |

|

Farmar precision |

± 0.5% |

|

Stroke precision |

0.01mm |

|

Volume method timing accuracy |

0.001S |

|

Displacement measuring encoder |

Omron photoelectric rotary encoder |

|

Testing scope of mass method |

0.1-150g /10min |

|

Test range by volumetric method |

50-5000cm³/10min (It can measure up to 5000 cm3/10min by using the plugging die ) |

|

Output way |

Micro automatic printout |

|

Blanking way |

Hand automatic cutting can be switched |

|

Test farmar ( weights) |

Total 8 grades, 8 sets of weights |

Introduction:

Plastic Rubber Melt Flow Index Test Equipment used for testing all kinds of plastic, resin in the state of viscous flow through a certain temperature and load, every 10 min module and melt flow rate through the standard port MFR value, it is suitable for high temperature of polycarbonate, aromatic sulfone, fluorine plastic, nylon and other engineering plastics, can also be applied to polyethylene (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyformaldehyde (POM), polycarbonate (PC) resin with lower melting temperature, suchas plastic test, widely used in plastic production, plastic products, such as petroleum and chemical industry and related colleges and universities, scientific research units, and the commodity inspection department.

Test Standard:

ISO 1133-2011 : Determination of mass flow rate (MFR) and volume flow rate (MVR) of thermoplastic melt

ASTM D1238 : Standard Test Method for Determining the flow rate of Thermoplastic Melt using an extruded plasmometer

GB/T3682-2018.1 : Thermoplastics: Standard Method for the determination of melt mass flow rate (MFR) and melt volume flow rate (MVR) of plastics

GBT3682.2-2018 : Melt mass flow rate (MFR) and melt volume flow rate of thermoplastics

Features:1. Chinese/English color touch screen display

2. Automatic hand cutting can be set

3. Double temperature control system, more precise temperature control, higher heating efficiency

4. It can connect to computer, output report by software, and export data by USB.

5. Double inlet sensor, the upper and lower temperature gradient is more accurate, can be used independently, improve service life

6. Input melt density, directly convert the result, can store 10 sets of data

7. The barrel is imported Harborite nitriding treatment, the mouth mold is made of carbon tungsten steel material, material

8. The insulation bucket is made of whole SUS304 stainless steel, which will not rust at high temperature for a long time

9. Automatically calculate the results and print them out