Technical parameters:

|

Mixing room total capacity |

5L |

|

Mixing chamber effective capacity |

1L |

|

Front and rear rotor speed |

50/40r/m |

|

Upper top bolt cylinder diameter |

100mm |

|

Compressed air pressure |

0.5~08Mpa |

|

Vapor pressure |

0.5 ~ 0.8Mpa |

|

Cooling water pressure |

0.2 ~ 0.4Mpa |

|

Mixing room flip angle |

130 °C |

|

Draw gate operation mode |

sliding |

|

Main motor |

4KM |

|

Flip motor |

0.5KM |

|

Volume |

1000*580*1300 (W*D*H) mm |

|

Weight |

700kg |

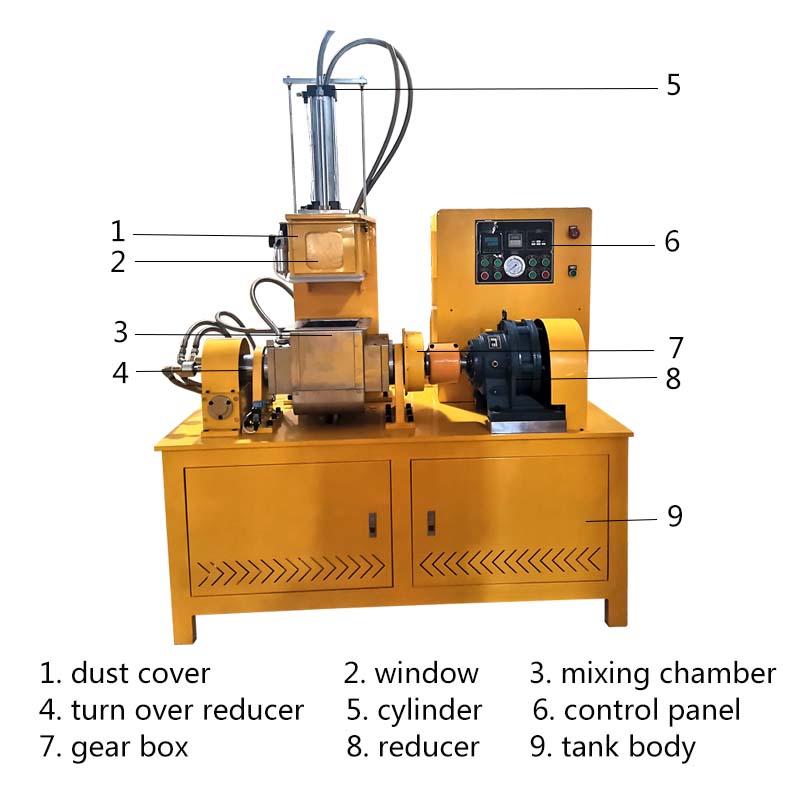

Equipment summary:

Banbury Internal Mixer with Taiwan technical drawings, advanced technology in China and imported core components, this machine has character itself as environmental-friendly, high-efficiency and good dispersing effect, with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production. It can also be used in electric wire, cable, electronics, sole, sports equipment and auto parts industries for rubber, plastic and chemical production mixing and plasticizing.

Detailed Product Description:

This Plastic Rubber Kneader Banbury Internal Mixer is applicable to rubber, plastic and chemical industry. And most suitable kneading application: EVA., rubber, TPR, sole, rubber roller, hoses, belts, sponges, vibration insulator, elastic cord, sealing materials, tire, tapes, master batches, pigment, ink, electric rubber parts, chemical industry compounds.

Advantages of Mixer mixing:

1. The mixing time is short, the production efficiency is high, and the quality of the rubber compound is good;

2. The operation capacity of the rubber filling capacity, mixing and other operations is high, the labor intensity is small, and the operation is safe;

3. The compounding agent has small loss of flying, low pollution and hygienic work site.

Pay attention:

1. Regularly check the insulation effect of each line, and always pay attention to the warning content on the machine warning sign.

2. When the moving parts and the mixing chamber are clogged, do not put them into the inside with your hands or iron bars, but use plastic sticks to handle them carefully.

3. Be careful not to get burnt when touching high temperature parts.

4. When there is a leaking powder or a squeaking sound of the sealing ring, first loosen the four screw caps evenly and then screw them in some, then add some material oil or oil in the gap of the rotor in the mixing chamber, then idling 3— At the same time, use a hammer to gently tap the periphery of the sealing ring of the spring side with a hammer. If the powder is leaking, adjust the tightness of the individual springs. If the sealing ring is pressed and the side chamber of the mixing chamber is sinking When it is close, the sealing ring inside is worn out and needs to be replaced again.

Refer to the instruction manual for the method of replacing the sealing ring.

5.Special attention: check the gear oil, oil and grease oil level and lubrication status before starting every day. Pay attention to the oil level of the triple oil cup should not be less than half every day, and observe the change of the triple oil level regularly. Fuel consumption or excessive fuel consumption is abnormal (to adjust the knob of the triplet), the gear oil of the new machine is replaced at the latest half a year, and the lubricating parts should be added at least once a week in the active part, and should not exceed half of the oil mirror when refueling. Otherwise it will cause oil leakage.

6. When the machine fails, the machine stops at the first time.

Unrelated personnel are not allowed to do any action, notify and wait for your mechanic to check and repair.