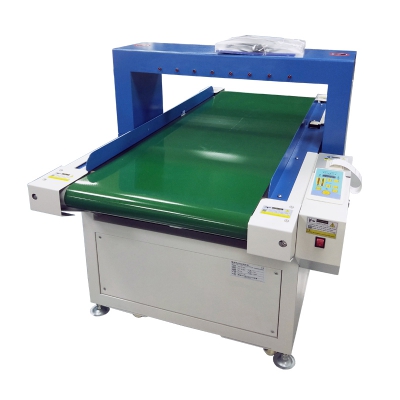

ZT-2003B Conveyor Belt Double Detector Socks Metal Needle Detector

Parameter:

|

Product Name |

Conveyor Belt Double Detector Socks Metal Needle Detector |

|||

|

Model |

ZT-2003 |

|||

|

Specifications |

6010 |

6015 |

6020 |

6010 |

|

Voltage |

Ac220V 50-60Hz |

|||

|

Motor power |

60W |

60W |

90W |

90W |

|

Material of the whole machine |

Carbon steel, ABS engineering plastics |

|||

|

Effective detection width |

600mm |

|||

|

Effective detection height |

100mm |

120mm |

150mm |

200mm |

|

Check the accuracy(empty) |

Fe≥φ0.7mm |

Fe≥φ0.8mm |

Fe≥φ1.0mm |

Fe≥φ1.5mm |

|

Height of conveyor belt above ground |

680mm |

|||

|

Belt width |

560mm |

|||

|

Effective load |

10KG |

15KG |

20KG |

|

|

Conveying direction |

From left to right |

|||

|

Max. speed of conveyor belt |

Constant frequency, 26 m/min |

|||

|

Material of conveyor belt |

PVC conveyor belt for needle detector |

|||

|

Display and operation mode |

Control panel key input |

|||

|

Alarm mode |

When the broken needle or magnetic metal foreign body is detected, the automatic buzzer will give an alarm and the conveyor belt will stop automatically |

|||

|

Protection level |

IP54 |

|||

|

overall length |

1650mm |

|||

|

overall width |

1050mm |

|||

|

Machine height |

900mm |

920mm |

950mm |

1000mm |

Quick detail:

Apply self-developed patent technology.

Equipped with latest microchip, reliable with excellent performance.

Sensitive and anti-jamming.

Automatically digital signal processing through the whole process.

Easy operate, history data can be processed and saved automatically before system switched off.

Self-designed high-frequency power switch.

Integrated and optimized design for reducing components, replaced electronic system by computer control, lower malfunction.

Microcomputer controlled motor to extend working life.

Precise counter device.

Feature and Application:

1. High sensitivity and strong interference immunity.

2. Light structure and move conveniently.

3. Various of specifications of inspection window which can be chosen at will according to customers‘ needs

4. Quick conveying speed, applicable to pipeline operation.

5. Matches the pipeline operation or automatic control device.

Application:

Mainly used for detecting ferrous metal that load or drop in raw materials and products in the field of toy costume, shoe making, chemical industry, leather, knitting etc. Clothes, textile, bra, baby products, shoes, socks, gloves, etc detection lost pin and scrap iron kind

of impurities in the products, ensure prduct without iron impurity pollution, supply reliable quality guarantee.