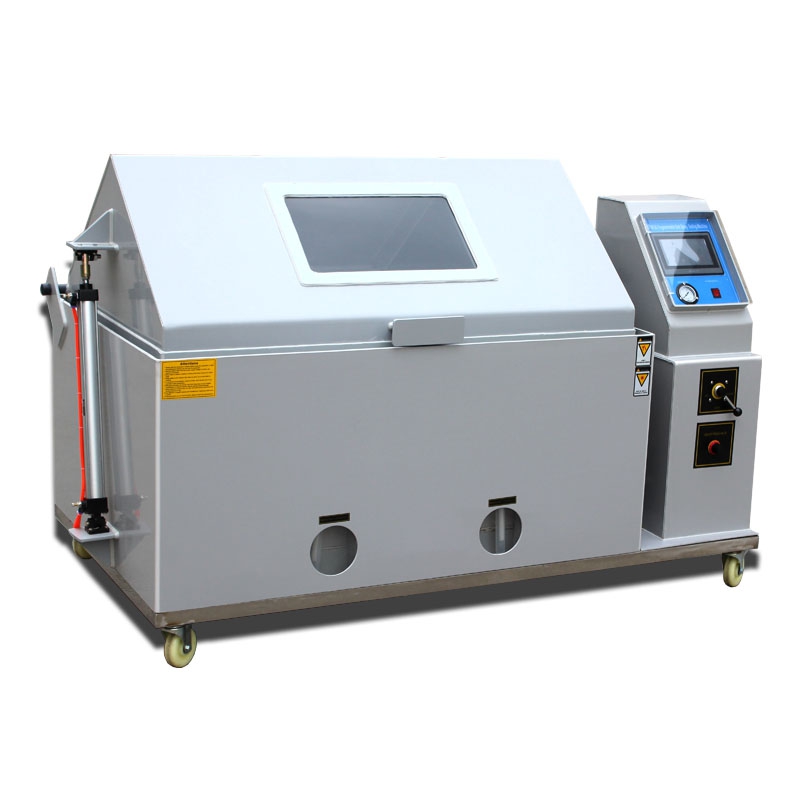

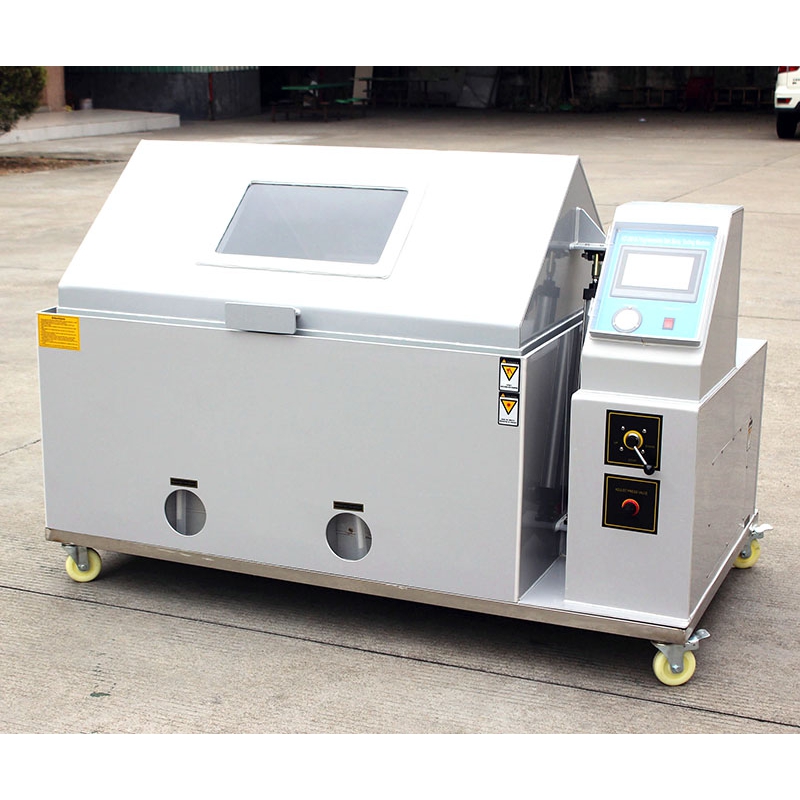

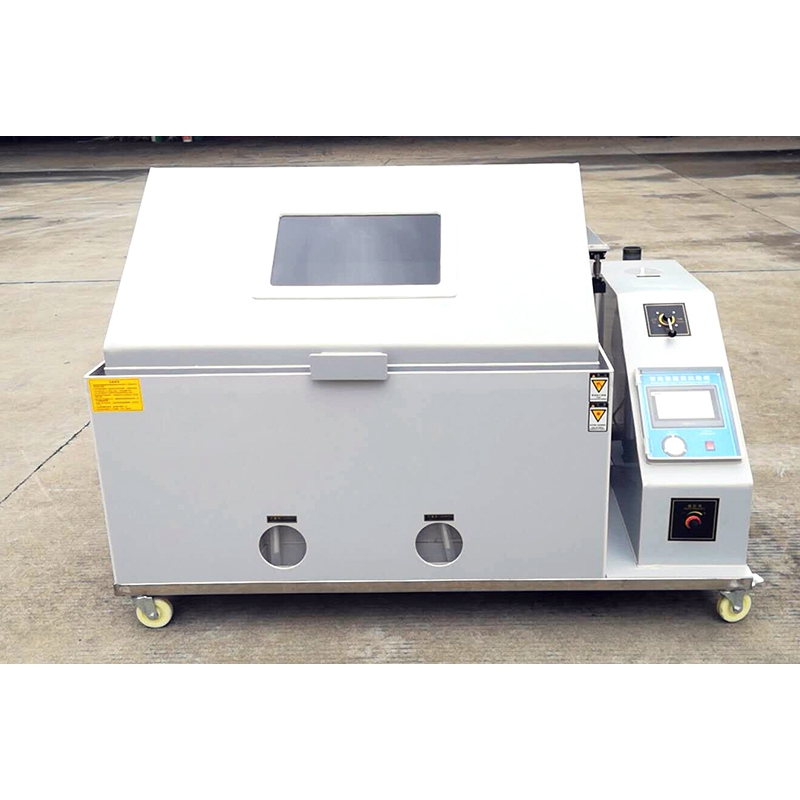

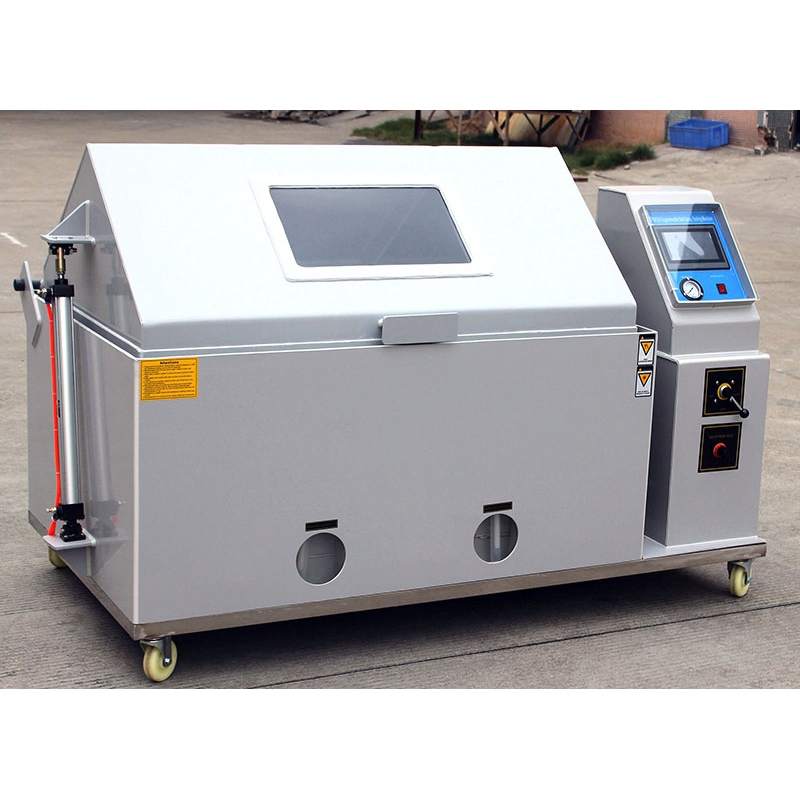

ZT-4002A Programmable Salt Spray Corrosion Test Chamber

Programmable Salt Spray Corrosion Test Chamber

Equipment summary:

Salt spray testing machine used to test the corrosive resistance of products whose the surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil,etc.

Technical parameters:

|

Model |

ZT-60 |

ZT-90 |

ZT-120 |

|

Inside box size(cm) |

60x45x40 |

90x60x50 |

120x100x50 |

|

Outside box size(cm) |

107x60x118 |

141x88x128 |

190x130x140 |

|

Testing room temperature |

Salt test (NSS ACSS)35℃±1℃/ Corrosion Test (CASS)50℃±1℃ |

||

|

Pressure barrel temperature |

Salt test (NSS ACSS)47℃±1℃/ Corrosion Test (CASS)63℃±1℃ |

||

|

Brine temperature |

35℃±1℃ 50℃±1℃ |

||

|

Testing room Capacity |

108L |

270L |

600L |

|

Brine tank capacity |

15L |

25L |

40L |

|

Salt concentration |

The concentration of sodium chloride 5% or the 5% concentration of sodium chloride add 0.26g per liter of copper chloride (CuCl2 2H2O) |

||

|

Air pressure |

1.00±0.01kgf/cm2 |

||

|

Spray volume |

1.0~2.0ml/80cm2/h (working at least 16 hours, and then take the average) |

||

|

Testing room relative humidity |

85% above |

||

|

PH |

6.5~7.2 3.0~3.2 |

||

|

Spray form |

Programmable spray (Including continuous and intermittent spray) |

||

|

Power |

AC220V1Φ10A |

AC220V1Φ15A |

AC220V1Φ20A |

Corresponding standard:

1.GB/T 2423.17-1993 salt spray test

2.GB/T 2423.18-2000 salt spray test

3.GB/T 10125-1997 salt spray test

4.ASTM.B117-97 salt spray test

5.JIS H8502 salt spray test

6.IEC68-2-11 salt spray test

7.IEC68-2-52 1996 salt spray test

8.GB.10587-89 salt spray test

9.CNS.4158 salt spray test

10.CNS.4159 CASS Accelerated acetic acid copper salt spray test

11.GB/T 12967.3-91 CASS Accelerated acetic acid copper salt spray test

2. According to CNS JIS ASTM GB2423.19 specifications, can be set constant temperature to control

(A) Salt spray test: NSS, ACSS

1. testing room : 35 ℃ ± 1 ℃

2. saturated air barrels : 47 ℃ ± 1 ℃

(B) anti-corrosion test: CASS (copper acetate)

1. testing room: 50 ℃ ± 1 ℃

2. saturated air barrels: 63 ℃ ± 1 ℃

3. Air supply system: air pressure 1Kg/cm2 Two-stage adjustments (coarse / fine-tuning).

(A) the first paragraph for the rough adjustment 2-2.5Kg/cm2, the second paragraph to fine-tune 1Kg/cm2.

(B) Testing configuration is switch connector designed for SO2.

4. Spray form:

(A) Using Bo Nute principle to draw brine and then saline spray, atomization uniform, non-blocking and crystallization, so that ensure continuous spraying.

(B) Nozzle: The nozzle is made of special glass, adjust spray volume and spray angle.

(C) spray volume: Adjustable 1 ~ 2ml (80cm2/hr) (average of 16-hour volume).

5. Heating devices:

By direct heating, warming up faster and reduction of standby time, when the temperature arrives automatically switch ON / OFF, make temperature accuracy, low power consumption (heating tube is made of titanium alloy).

6.The control system:

(A) testing room temperature controller is the digital micro-computer products 0-99.9 ℃, liquid crystal digital display with PID automatic calculation, the control error is ± 0.3 ℃ (YANG MING6802) 1 pcs.

(B) saturated air barrels controller 0 ~ 99.9 ℃, liquid crystal digital display with PID automatic calculation, the control error is ± 0.3 ℃ (YANG MING6802) 1 pcs.

(C) safe temperature controller of heat expansion of the liquid tank 30 ~ 110 ℃ (Italy) 1 pcs.

(D) safe temperature controller of expansion of the saturated air barrel : 30 ~ 110 ℃ (Italy) 1 pcs.

(E) digital time controller 9.9s ~ 9990hr (Taiwan) 1 pcs.

(F) timer 0 ~ 9999hr (Taiwan Anliang) 1 pcs.

(G) buckle switch, continuous buckling 20000 times.

(H) 60 type, 90 type for manual flip, 120, 160, 200 type for the pneumatic cylinde automatic opening and closing.

(J) pressure gauge, (Taiwan B card).

(K) fixture bleaker (YANG MING).

(L) electromagnetic valve; (KSD).

(M) regulating valve (YIHUA).

(N) bleaker (Omron).

7.Add water systems:

Using automatic water replenishment system, automatic replenishment when the water level is too low.

8.Safe protective device:

(A) low water level, automatically cut off power supply.

(B) over-temperature, automatic cut off the power supply.

(C) attached to the safe warning light device.