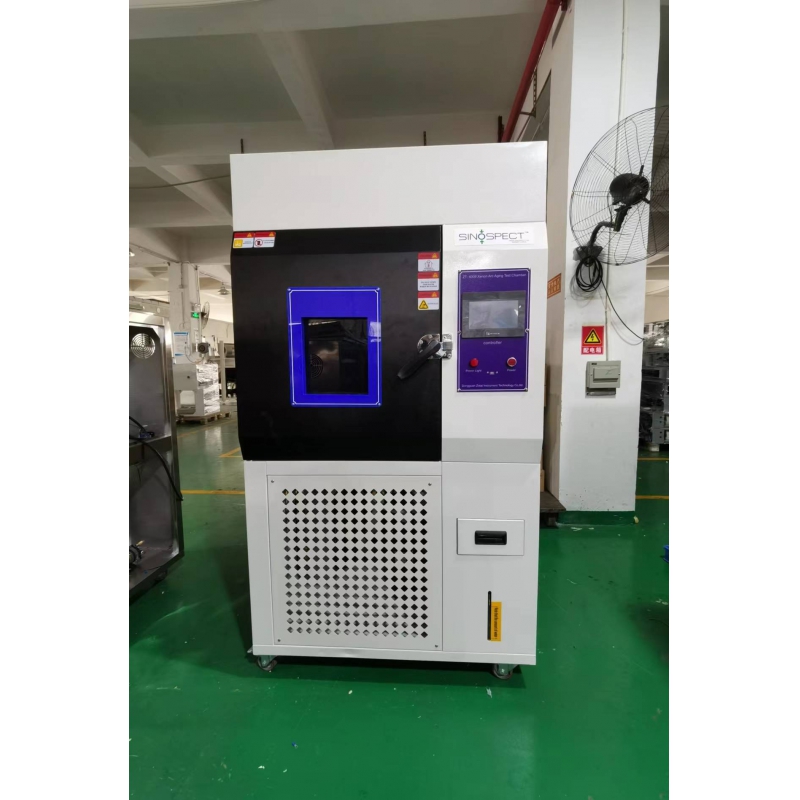

Xenon Lamp Weather Resistant Testing Machine

Equipment summary:

Best Price Xenon Lamp Weather Resistance Test Chamber is a comprehensive climate testing machine, in addition to climatic aging test, the lightfastness of materials can be carried out to test, polymer materials exposed at simulated sunlight. It simulates the light, temperature, rainfall, condensing, humidity to test the materials; it can be used for choosing new materials, improving existing materials, or assessment of change in material composition;

Technical parameter:

|

Testing room D×W×H |

500*600*500mm; 800*800*800mm or customized |

|

|

index |

Temperature range |

RT+10℃~80℃ |

|

Humidity range |

65~98%R·H |

|

|

Spray time |

1~9999min, adjustable |

|

|

Spray cycle |

1-240min, interval adjustable |

|

|

spectral wavelength |

290nm~800nm(60w/m2 / 150w/m2 / 7360w/m2) |

|

|

light source |

xenon lamp(air-cooled) |

|

|

Xenon lamp power |

1kw,6kw(longevity:1600H) |

|

|

Temperature and humidity control |

Time controller |

Import controller from Moeller |

|

Accurate range |

Temperature: ±0.1℃,/ humidity: ±0.1℃R·H |

|

|

Sensor |

Platinum resistance Pt100Ω/mv |

|

|

Heating system |

Independent system, nickel chromium alloy electric heating type heater |

|

|

Humidity system |

stainless steel, external Isolated humidifier |

|

|

Blackboard temperature |

Bimetal thermometer blackboard 55℃~75℃ |

|

|

Water supply |

Humidification water supply with automatic control, xenon lamp cooled by water recycling |

|

|

Temperature controller |

Import controller |

|

|

humidity |

Irradiation: 30%~65%RH darkly: up to 90%RH |

|

|

Cycle system |

low-noise air-conditioning-type motors, multi-leaf-type centrifugal wind wheel |

|

|

material |

Outside material |

Advanced spray color plate /SUS304 stainless steel |

|

Inside material |

SUS304 stainless steel |

|

|

Sample holder material |

SUS304 stainless steel |

|

|

insulation |

High and low temperature aging of silicone rubber |

|

|

standard |

a set of radiation-proof glass window, dynamic testing sample shelf 1, xenon lamp tube 2 |

|

|

protector |

Leakage, short circuit, over-temperature, water shortages, motor overheating, over-current protection. |

|

|

Power |

AC380V±10% 50±0.5HZ, Three-phase five-wire system |

|

|

Environmental temperature |

±5℃~+30℃ ≤85%R·H |

|

Main functions:

Make the samples exposed to the high temperature and alternating back to the circle of light and moisture environment to test the materials. This machine use xenon lamp tube to simulate the sunlight radiation, and use condensation water and spray water to simulate the dew and rain. This instrument only use a few days or weeks time, to realize the condition or the parts aging damage state in outside environment in few months or years. Including fade, color change, fracture, crack, wrinkle, foaming, embrittlement, strength reduction, oxidization and so on.

Corresponding standard:

Applicable industries:

Best Price Xenon Lamp Weather Resistance Test Chamber applied to control the product quality, such as electronic, plastic products, electrical appliances, instruments, food, vehicles, metals, chemicals, building materials, aerospace, medical care and so on.

Main feature:

Best Price Xenon Lamp Weather Resistance Test Chamber (vertical climate resistance) the cold rolled steel sheet electrostatic pensu or high quality stainless steel sheet, the tank for high quality stainless steel plate. Radiation light source is the solar spectrum xenon lamp, automatically track irradiation intensity, precisely control the blackboard temperature, irradiation cycle, dark cycle, spray cycle all can set according to relevant test standards or customer‘s requirements. Xenon lamp box (desktop weather resistance test) according to the user‘s controller to choose imported touch screen control instrument or intelligent digital display controlling instrument.

Xenon lamp climate resistance test box with ultraviolet radiation sensors, it can amend the aging tube or any other changes in the light energy decrease in time. Ultraviolet radiation sensors allows you to select proper light irradiation during the test. Ultraviolet radiation sensors can monitor indoor light irradiation intensity continuously, and by adjusting the power of tubes, can accurately keep the irradiation intensity in operation value.

Water spray cycle can effectively simulate temperature changing and rain erode process. Because of the rain was often flush, coating layer of lumber(including paint and coloring), will have erosion phenomenon. Recent research results show that the rain layer washed the material itself thus the materials are directly exposed to UV and water. The rain spray function can reproduce such environmental conditions, and enhance some paint climate aging test.

Equipment safety protection device:

1.Power overload, short circuit protection

2.ground protection

3.over temperature protection

4.Water shortage protection

5.In order to protect the equipment,All alarm will automatically cut off power supply,and with audible reminder

Operating conditions:

1. Temperature:15℃~35℃

2. Relative humidity: less than 85%RH

3. Without strong vibration and strong electromagnetic field

4. Without high concentration of dust and corrosive materials in round field

5. No direct sunlight or other sources of heat radiation directly

6. Without a strong airflow around,when need forced air flow around,air should not be blown directly to the body

7. Test cases should be placed stably, level

8. The sides of the test chamber should keep a certain distance, convenient maintenance operation.

9. Installation site well ventilated

10. Ground Benign