ZT-5025 Lacquer Wire Stripping Machine Insulation Paint Scraper

The enameled wire stripping machine adopts the latest designed ultra hard material high-speed stripping blade, which can cut and remove any hard insulation paint, enamel paint, ML, lsonel, etc. on the wire surface without damaging the copper wire itself. Especially suitable for situations where paint needs to be peeled off until the bottom of the coil, it is easy to operate and has excellent results.

The enameled wire stripping machine is equipped with a stripping length termination device, which can accurately control the stripping length of the enameled wire. Without serious pollution or harm, the stripping work is fast and safe.

Technical parameter:

|

Paint stripping wire diameter range |

AWG29-8 (0.2-4.0mm) |

|

Machine weight approximately |

5.2KG |

|

Machine size |

280*200*230mm L*W*H |

|

Working voltage |

220V 50HZ |

Knife head model:

|

TF2 |

Applicable wire diameter range of blade: 0.28-0.51mm |

1PC |

|

TF3 |

Applicable wire diameter range of blade: 0.51~0.81mm |

1PC |

|

TF4 |

Applicable wire diameter range of blade: 0.81~1.30mm |

1PC |

|

TF5 |

Applicable wire diameter range of blade: 1.45~1.83mm |

1PC |

|

TF6 |

Applicable wire diameter range of blade: 1.83-2.31mm |

1PC |

|

TF7 |

Applicable wire diameter range of blade: 2.31-2.90mm |

1PC |

|

TF8 |

Applicable wire diameter range of blade: 2.90~3.25mm |

1PC |

Installation and use:

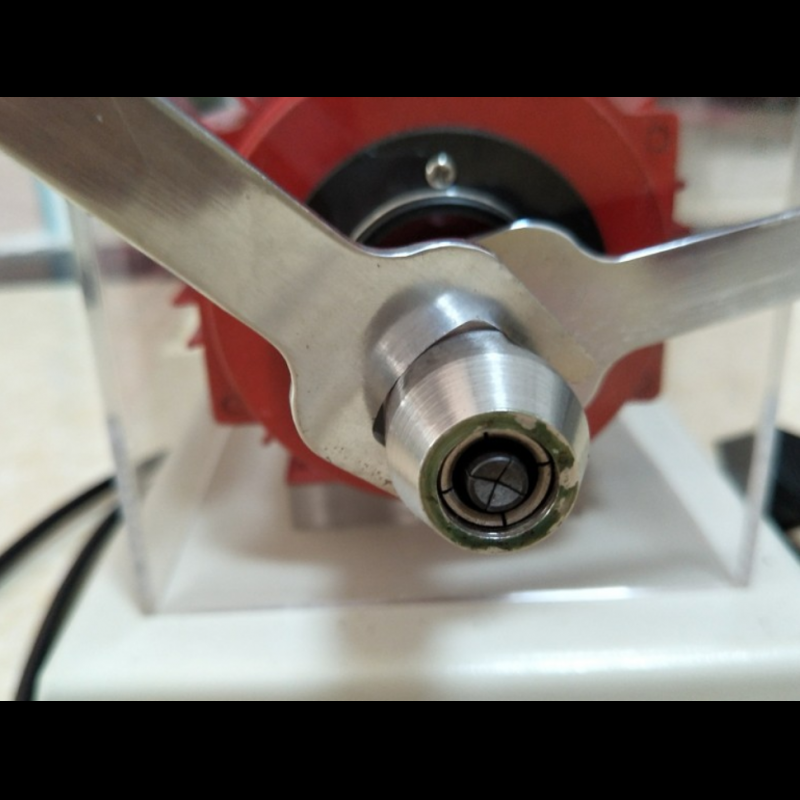

1. According to the blade specifications in the blade table, select the appropriate blade and install it on the front clamp of the machine. Insert an enameled wire into the middle of the blade and use a fixed wrench to adjust the clamp so that the blade gently clamps the enameled wire

2. Then exit the enameled wire, activate the switch, hold the coil part in hand, and easily push the enameled wire into the high-speed rotating blade until it reaches the pre-set stripping length. Then carefully exit the enameled wire, and the stripping work can be completed

3. When necessary, the diameter of the cutting head can be adjusted by loosening and tightening the clamping head to achieve the desired paint removal effect, because when the machine is running and the cutting head rotates at high speed, the insulation paint or oxide of the enameled wire is removed, and the surface of the enameled wire and copper wire after paint removal is bright and clean.

4. Set the desired paint stripping length by loosening the fixing screw of the clamp. After exiting the clamp, see the limit pin for the paint stripping length. Adjust the limit pin by fixing the screw to set and control the paint stripping length of the enameled wire.