Application:

Used for lining bonding, non-marking adhesive setting, leather/upper pressing, hot stamping,whole roll fabric bonding. Suitable for garment factory, shoe factory, automotive interior and other industries.

Summary:

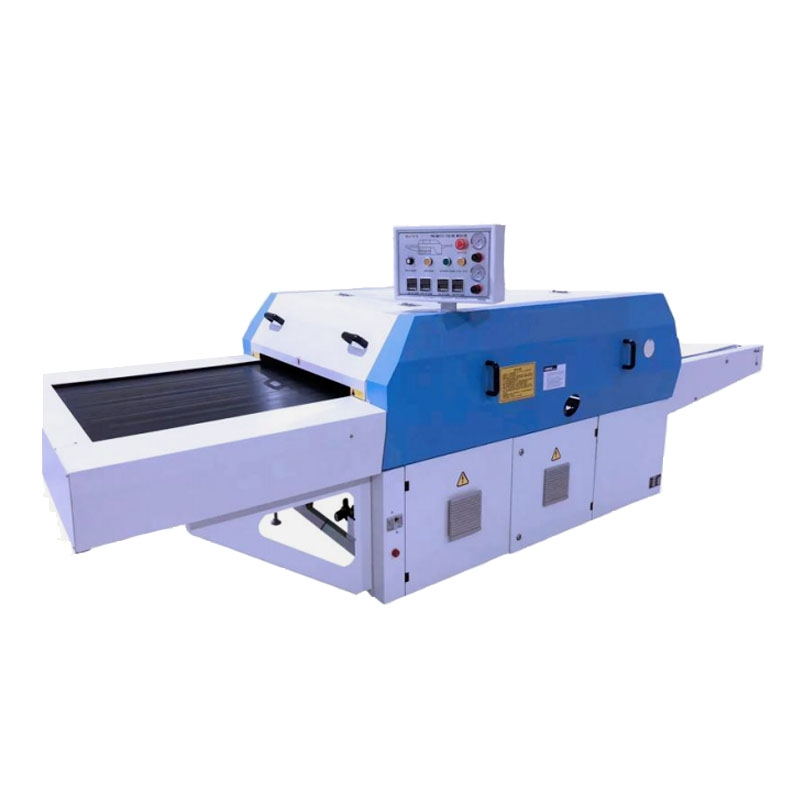

This double pressure roller pneumatic hot melt bonding machine is suitable for the hot melt bonding processing of various types of lining fabrics in the clothing manufacturing industry, especially for high-strength hot pressing and shaping in the shirt processing industry.

The discharge port of this machine is equipped with a forced air cooling system, which can quickly shape after bonding. Therefore, the fabric processed by this machine has advantages such as strong adhesion fastness, flatness, washing resistance, and less wrinkling. This machine is a seamless rolling and continuous hot pressing process, resulting in high production efficiency. This machine can also heat shrink and shape various fabrics. The control system of this machine adopts a programmable controller for control, which has strong adaptability and reliability.

Product features:

1. Pneumatic dual channel rolling, pressure can be adjusted separately.

2. Automatic pneumatic correction system.

3. The electric heating plate and shovel plate base are all made of drawn aluminum profiles,which are evenly heated.

4. Forced air cooling control at the discharge port.

5. Rotating synchronous belt stripping device.

6. Automatically cut off the heating power supply and turn on the conveyor belt cooling system during delayed shutdown.

7. Delayed shutdown is controlled by both temperature and time, and automatically cuts off the power supply within 10 seconds.

8. Automatic alarm for machine operation failure.

Technical parameters:

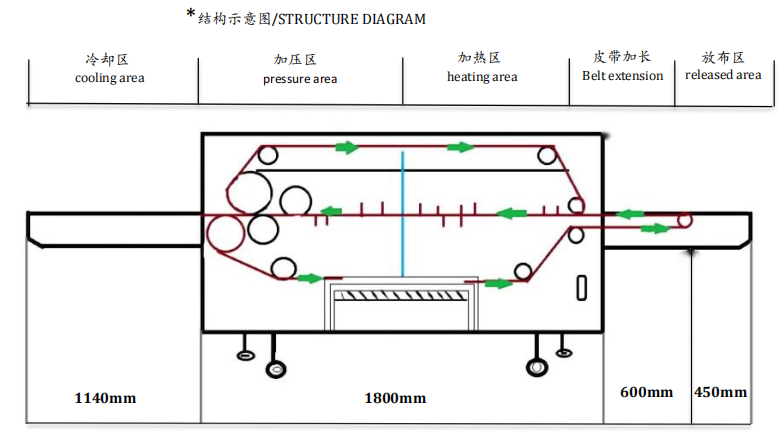

|

Heating length |

1800mm |

|

Work speed |

0-15m/min |

|

Temperature |

0-230℃ |

|

Working width |

900mm/1200mm |

|

Steam pressure |

Pneumatic |

|

Power supply |

AC 380v / 50HZ |

|

Air pressure |

0.4-0.7Mpa |

|

Heating material |

Mica plate |

|

Conveyor |

Seamless tape |

|

Number of heating plates |

11/18groups |

|

Total Power |

18KW/22KW |

|

Machine size |

3980*1225*1200mm / 3980*1525*1200mm |

|

Weight |

785kg/930kg |