Technical parameters:

|

Mixing capacity |

0.2L |

|

Feed quantity |

50g ~ 200g(depending on materials) |

|

Temperature |

±2℃;normal temperature ~300℃ |

|

Heating mode |

heating pipe (400w x 8 pics) |

|

Cooling method |

tap water cooling (customer provides cooling water interface) |

|

Control mode |

program control |

|

Program control system |

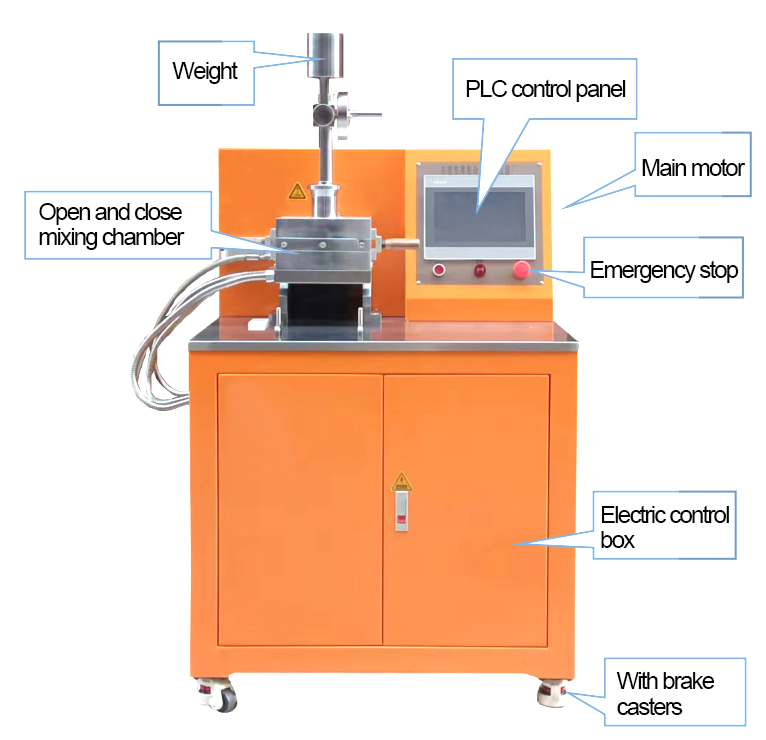

10 inch PLC touch screen |

|

Heating power |

3.2KW |

|

Main motor |

1.5KW (Siemens, Germany) |

|

Upper weight |

5kg weight on the weight |

|

Rotor revolutions |

0~70rpm Frequency converter adjustable |

|

Rotor speed ratio |

1:1.27 |

|

Rotor material:

|

DC53, surface chrome plating, hardness ≥62HRC, surface shot polishing, polishing chrome plating and other treatments (high toughness, wear resistance, high temperature resistance) |

|

Rotor hardness

|

Rotor after vacuum heat treatment, chrome plated surface, hardness ≥62HRC |

|

Mixing chamber

|

D2 alloy steel, inner chamber surface hard chromium, hardness ≥60HRC, surface grinding, nitriding, polishing and other treatment (corrosion resistance, wear resistance) |

|

Disassembly mode

|

The otor and the cavity are detachable, which can separate the tightly mixed cavity and the side plate completely. The rotor can be easily disassembled, which is easy to take and clean the materials on the cavity, the side plate and the rotor |

|

Safety protection function

|

overload protection; Emergency stop switch |

|

Caster |

Brake caster, easy to move and fix |

|

Power |

AC380V, three-phase five-wire |

|

Volume |

800*1000*15000mm |

|

Weight |

about 350kg |

Equipment summary:

Lab Banbury Rubber Kneader Mixer Machine referred to as mixing machine, also known as kneading machine, mainly used for rubber, plastic mixing. The mixer is a kind of machine with a pair of specific shape and relative rotation of the rotor, in the closed state of adjustable temperature and pressure clearance to polymer material plasticizing and mixing, mainly by the mixing chamber, rotor, rotor sealing device, feeding and pressing device, unloading device, transmission device and frame and other parts.

Working principle:

When the mixer works, the two rotors relative rotation, the material clamped into the roll seam by the rotor extrusion and shear, the material by shear and friction, so that the rubber temperature rise, viscosity reduction, increase the rubber in the surface wetting, so that the rubber and the surface of the compound full contact, the rotor flange makes the rubber along the axial movement of the rotor to play the role of mixing. The compound is evenly mixed in the rubber, and the continuous stirring of the rotor flange and repeated shear breaking make the rubber reach a certain dispersion.

Application:

Mainly used for natural rubber and other polymer elastomer plasticizing and mixing, also used for plastics and a variety of synthetic resin mixing, but also used for asphalt material, felt material, synthetic resin mixing.

Mixing of all kinds of cable materials, color master materials, EVA, PVC, calcified materials and high filling engineering materials. Special equipment for mixing raw materials of metal powder such as iron oxide and stainless steel powder.