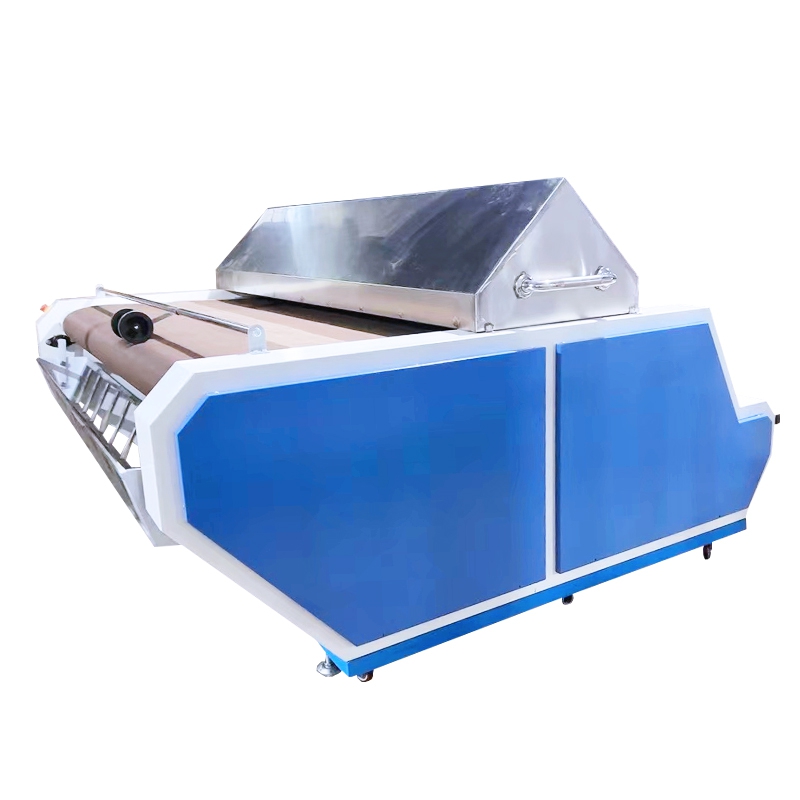

Machine introduce:

Fabric Steam Shrinking Equipment is a machine that uses synthetic processes such as heat, pressure, and moisture to treat cellulose fabrics to the desired shape and size. Setting machines are widely used in textile mills, playing a crucial role in shaping, compressing, and adjusting the shape of cellulose fabrics.

Machine applications:

Fabric Preshrinking Setting Equipment suitable for knitting and various general surface treatments

Features:

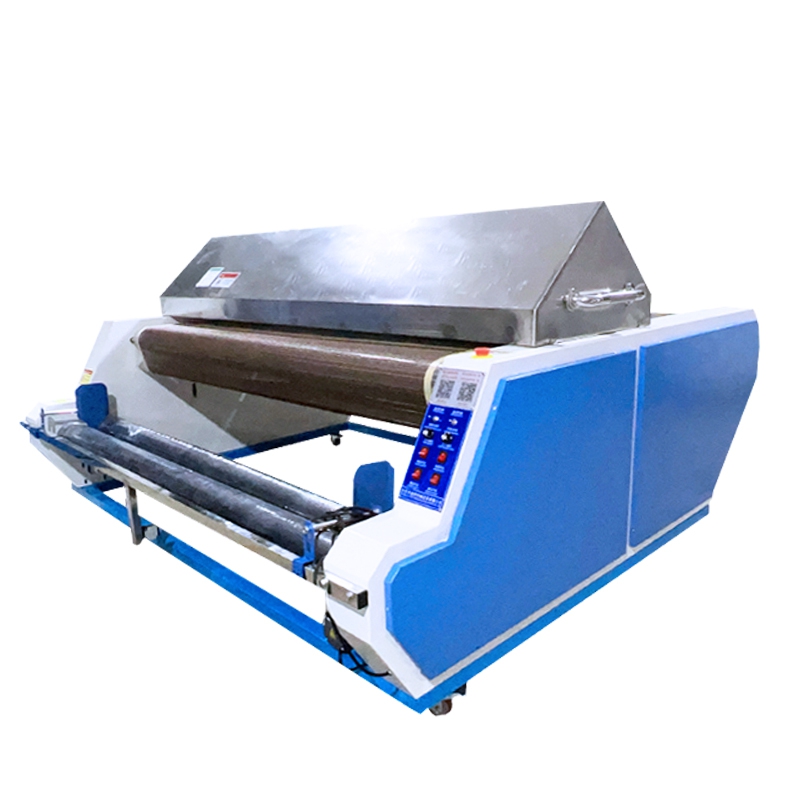

1. This machine is composed of two parts: steam box shrinkage molding, and drying box (drying molding)

2. Dual frequency converter control, protecting the motor from overload and overvoltage, variable frequency speed regulation.

3. Automatic fabric feeding device: ensures a certain sag between the fabric and the conveyor belt, allowing the fabric to be conveyed in a tension free state, preventing fabric elongation and deformation

4. Infrared electronic eye sensing automatically shuts down when there is no fabric to be fed

5. Unloading device: The fabric is folded into a piece of cloth through a cloth rack, neat and without wrinkles (optional winding device, rewinding, rewinding)

6. Code counter: Accurately measuring fabric length and shrinkage;

7. Steam oven and drying oven, all made of thickened 304 stainless steel

8. This machine is equipped with a Teflon high-temperature mesh belt, and the advantage of Teflon material is its high temperature resistance

Machine parameters:

|

Usage width |

2100mm |

|

Steam consumption |

80kg/H |

|

Temperature |

125°C-150°C |

|

Voltage |

220V/50Hz |

|

Processing speed |

0-50Y/min |

|

Steam pressure |

0.7/MPa |

|

Body size |

2300 * 2500 * 1500mm |

|

Power |

1.5KW |