Introduction:

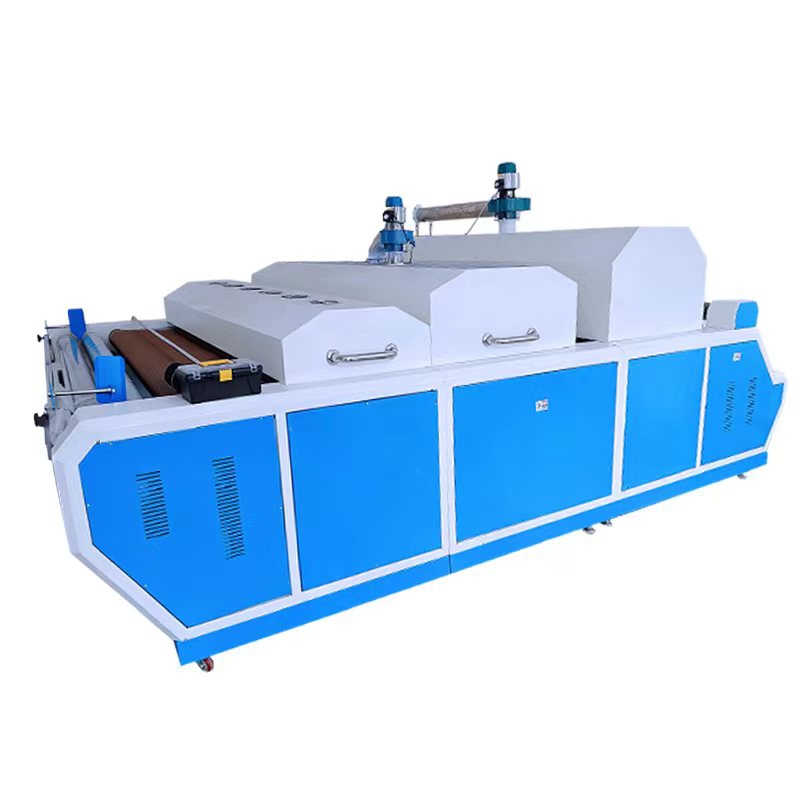

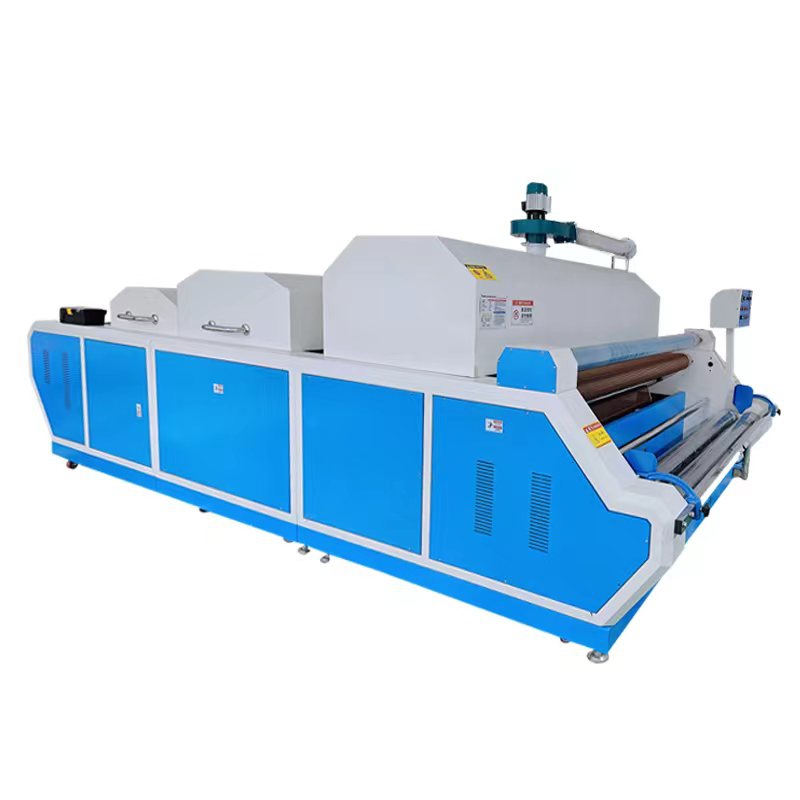

Textile shaping machine is a machine that uses synthetic processes such as heat, pressure, and moisture to treat cellulose fabrics to the desired shape and size. Setting machines are widely used in textile mills, playing a crucial role in shaping, compressing, and adjusting the shape of cellulose fabrics.

Applications:

Suitable for Linen, cotton fabric, knitted fabric, woven, non-woven cotton, quilting, curtains, bedding, cloth toys, leather, artificial leather, jacquard cloth, towel colth, chemical fabrics manufacturers use.

Parameters:

|

Usage width |

2100mm |

|

Steam consumption |

150kg/H |

|

Temperature |

125°C-230°C |

|

Voltage |

380V/50Hz |

|

Processing speed |

0-60Y/min |

|

Steam pressure |

0.7/MPa |

|

Body size |

4800 * 2680 * 1650mm |

|

Power |

36KW |

Features:

1. This machine is divided into three parts, steam box shrinkage, drying box (drying), cooling box (air cooling)

2. Three inverter control, protect motor overload and overvoltage, variable frequency speed regulation, 0 to 60 meters per minute.

3. Automatic cloth feeding device: ensure a certain vertical arc between the fabric and the conveyor belt, so that the fabric is transmitted in a state of no tension, to prevent fabric stretching and deformation

4. Heating device: The upper and lower ends of the electric heating and steam cycle, all aluminum mica heating sheet, to the steam box twice heating, no water, dry and soft fabric

5. Comb and pull edge cloth device screw

6. Infrared electronic eye sensor, no cloth stop, when there is no fabric behind the cloth, infrared electronic eye sensor automatic stop

7. With vibrating cloth device, effectively repair pinholes, trachoma, twill.

8. The steam temperature is adjusted according to the requirements of the cloth, the temperature is adjusted to 125°C~230°C, and the temperature is fast

9. Cooling device: Strong suction cooling system can completely cool and shape the fabric:

10. Air hood device: absorb the residual steam in the humidification area, make the workplace air fresh:

11. Cloth unloading device: Fold the cloth into cloth by the push frame, or roll neatly:

12. Code meter: accurately measure cloth length and shrinkage;

13. Steam box, drying box, all use thickened aluminum bottom plate, 304 stainless steel box lid

This machine is equipped with Kevlar high temperature net belt, electric eye automatic correction, the advantages of Kevlar material: high temperature resistance - corrosion resistance