Difference between ZT-1612 and Ordinary Portable Colorimeter

ZT-1612 with φ20mm extended aperture and stable end face can test surface stripe and wet products.

When testing products such as meat by ordinary colorimeter, the whole instrument body has to be placed in the object which not only stains the instrument, but also will let the liquid/water enter the instrument directly and bring cross contamination. However, this colorimeter is a vertical structure. When measuring, it can make sure only the aperture touches the object which will not stain the instrument body.

Product Introduction

This colorimeter is a handhold colorimeter based on 45°/0° optical geometry. Its measuring aperture is 20mm. It measuring aperture is the biggest one in domestic. Meanwhile, it also has high measuring precision. As a member of 3nh 45°/0° colorimeter, the colorimeter with unique performance. The color measurement results simulate human eyes but its accuracy is several times higher than human eyes. 45°/0 ° optical geometry structures can reflect interactive effect between surface stripe and sample color more effectively than 8°/d colorimeter. It will eliminate the errors between human eyes and color tester caused by surface stripe when judging tolerance critical value of sample colors. Therefore, this colorimeter is widely used in color field.

QC Department

Colorimeter can meet quality control requirements in plastic (PET,PE,PP,PTA,ABS,EVA particles and powder), color steel plate, coating, textile, fluorescent material, denim, medicine and food industries, etc. It can help to control product color difference, improve product competitiveness, reduce enterprises’ loss and control production cost.

Applications

Food, medicine, textile, non-woven fabrics, denim, dyeing and printing, color steel plate, paper, plastic, chemical, coating, ink, building material industries, etc.

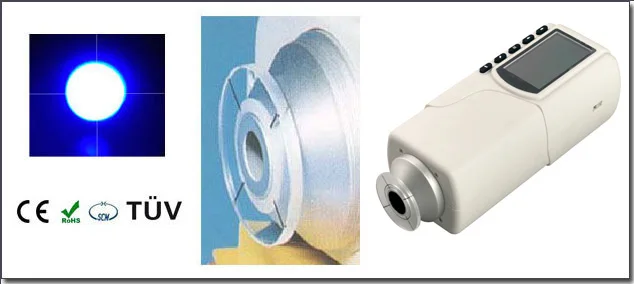

Illumination Locating; Cross Locating; Large Stable End Face

Technical Specifications

|

Model |

Precision Colorimeter |

|

Illuminating/Viewing Geometry |

45°/0° |

|

Measuring Aperture |

Φ20mm |

|

Special Function |

Especially suitable for testing surface stripe and wet products |

|

Locating |

Illumination Locating/Cross Locating |

|

Detector |

Silicon photoelectric diode |

|

Locating |

Illuminating Locating/Cross Locating |

|

Color Space |

CIEL*a*b*C*h*; CIEL*a*b*; CIEXYZ |

|

Color Difference Formula |

ΔE*ab; ΔL*a*b*; ΔE*C*h* |

|

Light Source |

D65 |

|

Light Source Device |

LED blue light excitation |

|

Errors Between Each Equipment |

≤0.50ΔE*ab |

|

Storage |

100pcs standards 20000pcs samples |

|

Repeatability |

Standard deviation within ΔE*ab 0.08 Average of 30 measurements of standard white plate |

|

Weight |

500g |

|

Dimension |

205×67×80 mm |

|

Power source |

Rechargeable lithium-ion battery 3.7V@3200mAh |

|

Lamp Life |

5 years, more than 1.6 million measurements |

|

Charging Time |

First charging time is 8 hours--100% electricity |

|

PC Software |

CQCS3 Software |

|

Printer (optional) |

Miniature thermal printer |

Product Advantages

1. 20mm measuring aperture can test objects with surface stripe accurately.

2. Vertical structure can test wet surface object or can be soaked into the liquid for testing.

3. Double Locating: Illuminating locating and cross locating.

4. Adopting new optical path and dynamic integration time can test more stable and accurate.

5. 45°/0° optical geometry structure, considering the effects of surface features.

6. Annular illumination design, suitable for polarizing material.

7. Equipped with rechargeable high-capacity Li-ion battery. No need to purchase battery repeatedly.

8. Configuring CQCS3 software -- connect PC computer to realize more functions.