Equipment summary:

Walk-in Salt Mist Corrosive Resistance Test Chamber used to test the corrosive resistance of products whose the surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil,etc.

|

1. Product attributes |

||||

|

Capacity |

1152L custom |

|||

|

Inner size |

800*800*800mm(D×W×H) custom |

|||

|

Outside size |

2760*1480*1780mm (D*W*H) |

|||

|

Power supply |

220V±10%,50Hz±1 |

|||

|

Total power |

7.5KW |

|||

|

Weight |

500kg |

|||

|

Operate and set according to JIS, ASTM, CNS, GB standard parameters |

||||

|

Salt spray test: NSS, ACSS |

||||

|

Laboratory temperature |

35℃±1℃ |

|||

|

Saturated air bucket temp |

47℃±1℃ |

|||

|

Corrosion resistance test: CASS |

||||

|

Laboratory temperature |

50℃±1℃ |

|||

|

Saturated air bucket temp |

63℃±1℃ |

|||

|

2. Main technical parameters |

||||

|

Temperature range |

R.T+10~55℃ |

Note: 1. All tests are carried out under empty container conditions. 2. The test conditions are room temperature ≤25℃, relative humidity ≤85%R.H, no load in the studio, 1/10 space away from the inner wall of the box, the temperature is constant for two hours. |

||

|

Settling amount of salt spray |

1~2ml/h80cm2 |

|||

|

Temperature fluctuation |

≤±0.5℃ |

|||

|

Temperature uniformity |

≤2℃ |

|||

|

Temperature deviation |

±2℃ |

|||

|

Heating time |

≤60min |

|||

|

Noise |

<70dB |

|||

|

Standards |

GB2423.17 GB/T10125-2012 ASTMB117-2011 |

|||

|

3. Structure |

||||

|

Test chamber material |

Box material: The inner and outer boxes are made of Taiwan light gray impact resistant PPR plate, the thickness is 10mm, and the temperature is about 85℃. The edge is reinforced around the three-dimensional thickness of 10mm, and the structure is firm. |

|||

|

The door of the test chamber is made of PPR board, with 300×400 transparent observation Windows with double thickened edges to prevent long-term distortion and deformation at high temperature. The thickness is 10mm. The door frame is sealed with silicone strips. |

||||

|

Box frame strength: The base of the test box is made of 304 stainless steel square steel, and the internal skeleton is made of stainless steel Angle iron and square steel. |

||||

|

Insulation thickness: 100mm hollow layer. |

||||

|

Liquid medicine tank |

Hidden integrated test refill box, easy to clean, easy to operate. |

|||

|

Saturated air bucket |

Made of 304 stainless steel, high pressure resistance 3Kpa, the best insulation effect. The internal heating tube is made of Taiwan Taizhan electric heat tube, and the water level is controlled by Taiwan Fanyi float switch, which is durable. |

|||

|

Sample placement |

The test bench is made of temperature-resistant ABS board with strong load-bearing capacity (200KG). Good water permeability to ensure easy access to the generator (with casters) |

|||

|

Moving caster |

None |

|||

|

4. Test chamber control system |

||||

|

Regulation method |

Air natural balance temperature control + liquid expansion natural constant temperature |

|||

|

Air temperature control |

The whole bottom of the test chamber is heated to achieve an equilibrium test temperature |

|||

|

Natural constant temperature |

The water temperature of the test tank is heated by the heater so that the heat naturally fills the whole test space. |

|||

|

Heating method |

Pure titanium alloy heating tube, acid and alkali corrosion resistance, long life; PID regulation, execution element: solid state relay |

|||

|

5. Operation control system |

||||

|

Independent electric control cabinet, made of 304 stainless steel, placed next to the test box. |

||||

|

controller |

Using LCD touch screen display controller, with microcomputer automatic calculation function, high control precision, all Chinese menu operation mode. The circuit board is treated by moisture-proof and anti-corrosion, and has a long life. |

|||

|

Electrical element |

The use of France Schneider, Japan Omron and other world famous brands |

|||

|

Precision class |

France Schneider, Japan Omron and other world famous brands |

|||

|

Mode of operation |

Set values and run the program |

|||

|

Program capacity |

20 programs, each with a maximum of 80 segments. Programs can be linked, and program segments can be looped. |

|||

|

Temperature sensor |

The laboratory temperature sensor adopts PT100 platinum resistance, the heating tank is protected by liquid expansion temperature controller 0 ~ 120℃, and the shell is treated with anti-corrosion. |

|||

|

Test data show |

Set temperature and humidity, measured temperature and humidity, total running time, period of running time, heating state |

|||

|

Power off memory recovery |

Power-off recovery Settings, including: program termination after power-off, program continuous operation from breakpoint after power-off. |

|||

|

Water refill function |

The equipment is equipped with automatic water inlet valve, automatic water supply according to the water level, the source of water is municipal tap water |

|||

|

Controller function display |

It can display the running time, the number of segments, the remaining time and the number of repetitions of the program in real time. Test data can be displayed, including set temperature and humidity, measured temperature and humidity, total running time, segment running time, segment remaining time, heating state, calendar time, etc. Temperature and humidity can be directly displayed digitally, and humidity setting and measurement are displayed with relative humidity represented by "%RH". |

|||

|

Time-lapse function |

Italian VEMER0 ~ 99999hr integrator is used |

|||

|

Man-machine dialogue function |

The RS232 communication interface extends its function to realize remote monitoring of the equipment. |

|||

|

6. Salt spray system |

||||

|

Spray principle |

The brine is absorbed by the Bernaut principle and then atomized, the atomization degree is uniform, and there is no blocking crystallization phenomenon, which can ensure the standardization of continuous testing |

|||

|

Spray element composition |

Composed of solvent tank, pneumatic system, bubble tower, nozzle, etc. |

|||

|

Solution tank volume |

≥50L |

|||

|

Solution tank volume |

Made of special glass nozzle, can adjust the size of spray amount and spray Angle |

|||

|

Brine atomization |

The brine atomized by the baffle, the mist diffused evenly and settled freely in the test chamber |

|||

|

Settling capacity |

The spray volume is adjustable from 1 to 2ml/h (ml/80cm2/h standard requires 16 hours of testing to average the amount). The measuring cylinder adopts built-in installation, beautiful appearance and neat, convenient observation, reducing the installation space of the instrument |

|||

|

Spray method |

Continuous or periodic spray |

|||

|

Air supply system |

The inlet pressure is controlled by the inlet pressure regulator valve about 0.4Mpa, and the water is drained through the oil-water filter separator, and then it enters the secondary precision pressure regulation control, and the pressure range is between 0.6 and 1.7Kpa. |

|||

|

7.Heating systerm |

||||

|

Using direct heating method, the heating speed is fast and the standby time is reduced. When the temperature reaches, the constant temperature state is automatically changed, the temperature is accurate, and the power consumption is less. Pure titanium heat pipe, acid and alkali corrosion resistance, long service life |

||||

|

8.Water charging system |

||||

|

Automatic and manual water adding systems are used to automatically or manually replenish pressure drums and laboratory water levels to prevent water shortage and ultra-high temperature damage to the instrument |

||||

|

9.Fog removal system |

||||

|

During the test process or shutdown, the salt spray in the test box should be manually removed to prevent the corrosive gas from flowing out and damaging other precision instruments in the laboratory |

||||

|

10.Test chamber safety protection device |

||||

|

Overtemperature protection |

Automatically cut off the power supply, sound and light alarm |

|||

|

Low water level protection |

Automatically cut off the heater power supply, alarm indicator light |

|||

|

Low water level protection of liquid medicine |

The safety warning light device lights up and gives an alarm |

|||

|

Power system |

Power supply phase sequence, overvoltage, undervoltage protection |

|||

|

Others |

Test chamber shell grounding protection |

|||

|

11. Test box standard accessories and random data |

||||

|

Product operating instructions |

1 |

|||

|

product certificate |

1 |

|||

|

Quality Guarantee Certificate |

1 |

|||

|

V-type/O-type storage rack |

1 |

|||

|

Measuring cylinder |

2 |

|||

|

Glass nozzle |

2 |

|||

|

Collector |

2 |

|||

|

Sodium chloride |

2 |

|||

|

12. Installation site and requirements |

||||

|

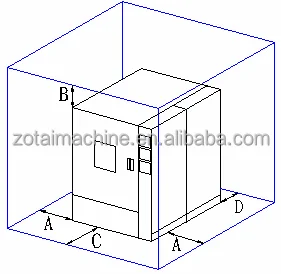

Site requirements and dimensions required for layout |

|

|||

|

A:≥30cm B:≥70cm C: ≥100cm D: ≥50cm |

||||

|

The ground is flat, well ventilated, free of inflammable, explosive and corrosive gases and dust |

||||

|

4 "tap water interface, compressed air interface (air pressure is 0.4MPa) |

||||

|

The drainage pipe must be no higher than 50mm above the ground |

||||

|

Conditions such as ambient temperature and humidity |

Ambient temperature requirements: 10 ~ 28℃ to ensure the best performance, 0 ~ 40℃ can operate normally. |

|||

|

Relative humidity: ≤ 90%RH |

||||

|

Ambient pressure requirement: 86KPa ~ 106KPa |

||||

|

Storage safety conditions: When the test chamber is not working, the storage environment of the test chamber should be kept > 0℃ |

||||