Overview:

This product is mainly used to measure the elastic modulus of concrete test block. The instrument is simple, light and convenient to use in test.

Meet standards:

GB 1971-89 test method for mechanical properties of aerated concrete

Gb81-85 test methods for mechanical properties of ordinary concrete

JTG-2005 test specification for cement concrete of highway engineering

ASTMC-469

Technical parameters:

| Suitable for concrete elastic modulus test block |

150×150×300mm,Φ150×300mm 100×100×300mm,Φ100×300mm |

| Range of dial indicator |

0 ~ 1mm |

| Center distance between upper ring and lower ring |

150 mm |

| Distance between lower ring and bottom |

75mm |

| Net weight |

5kg |

Structure:

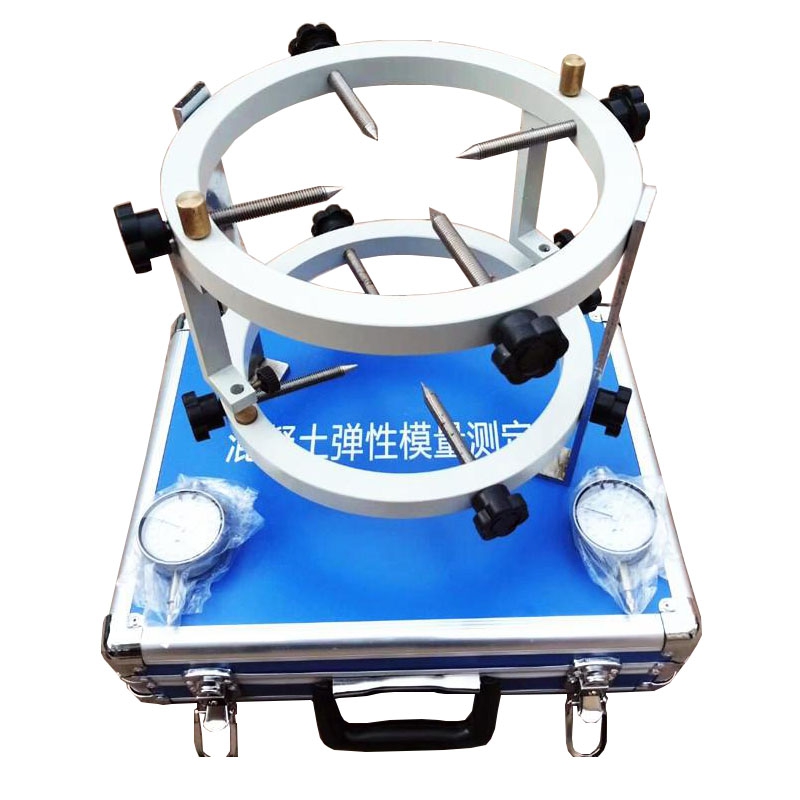

1. There are two kinds of concrete elastic modulus measuring instruments: round and square.

2. The tester consists of upper ring, lower ring, contact rod, dial indicator and set screw.

Operation method:

Before the test, place the elastic modulus tester on a flat plane, screw out the set screw of the test block, put the cured formed concrete test block into the tester ring, screw the set screw of the test block, install the dial indicator, loosen the set screw of the fixed plate, and remove the fixed plate, then the tester has been positioned on the test block. Place the tester together with the test block on the lower pressing plate of the pressure testing machine, align the center of the test piece with the center of the lower pressing plate of the press, and set the dial indicator to zero.

Start the press, when the upper pressing plate is close to the test piece, adjust the ball seat to make the contact balanced, continuously and evenly load Pa at the speed of 0.2 ~ 0.3mpa/s, and then unload to zero at the same speed, so as to repeatedly preload for 3 times. During preloading, observe whether the press and dial indicator are normal. The deformation difference of the dial indicator on both sides of the specimen shall not be more than 15% of the average value of deformation, and shall not be positive or negative.