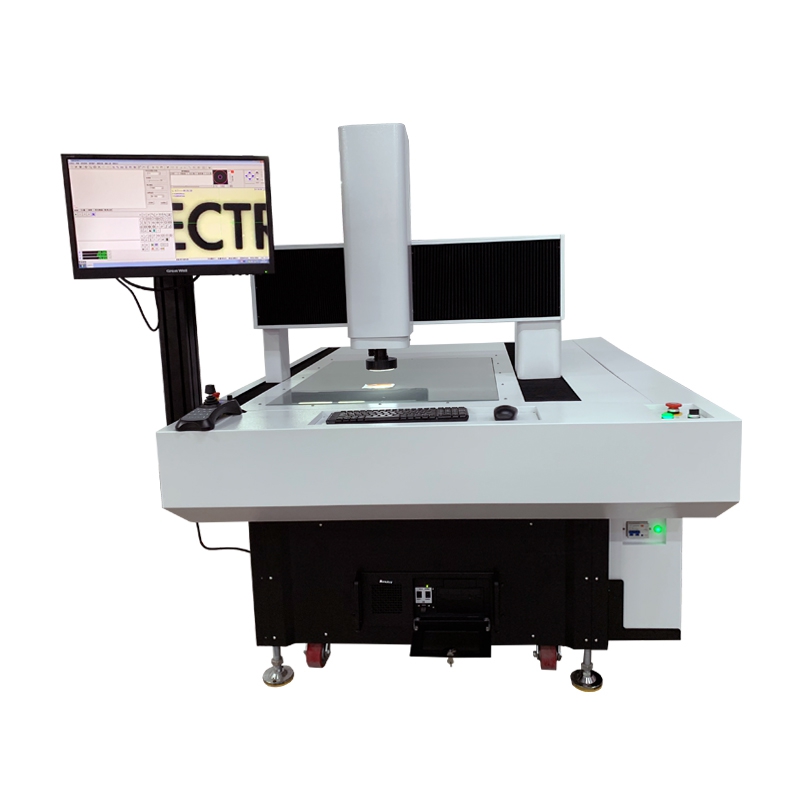

Technical Parameters:

|

Model |

AM500 |

AM600 |

AM800 |

AM1000 |

|

|

Measuring Range (mm) XYZ |

500*400*200 |

600*500*200 |

800*600*200 |

1000*800*200 |

|

|

Weight (kg) |

1100 |

1450 |

1800 |

3300 |

|

|

loadweight (kg) |

30 |

30 |

30 |

30 |

|

|

X, Y axis precision(μm) |

3.0+L/200 |

||||

|

Z axis accuracy (μm) |

5.0+L/200 |

||||

|

repeatability (μm) |

0.003 |

||||

|

X, Y axis movement speed |

0-600mm/S(can optional) |

||||

|

Z axis movement speed |

0-100mm/S(can optional) |

||||

|

operating way |

Rocker + software |

||||

|

Grating ruler |

“RENISHAW” metal linear scale with resolution 0.001mm |

||||

|

Guide |

Taiwan "silver" SP ultra-precision level (parallel degree of accuracy of 0.003) mm or less (walking) linear guide |

||||

|

Screw |

Taiwan TBI" grinding ball screw |

||||

|

Bearing |

Japan‘s original "NSK" double combination centripetal ball bearings |

||||

|

Motor |

"Panasonic" ac synchronous servo motor, positioning accuracy with 0.002 mm or less |

||||

|

Motion controller |

SBK4000 (full closed loop controller) |

||||

|

Photoelectric limit switch |

Japan‘s original "omron" photoelectric limit switch |

||||

|

Rocker |

Germany type "MEGATRON" hall style three-axis joystick |

||||

|

Camera |

SBK - HC600 1/2 inch 700 line color high definition camera (with the white balance function) |

||||

|

video card |

Beijing "it" high-resolution dual color video card |

||||

|

Lightsource |

Profile illumination |

LED cold light source, light transmitted light with focusing lens to achieve parallel light exposure |

|||

|

Surface illumination |

4 ring 8 partition LED cold light source, software control, reduce the damage of electrical components. |

||||

|

Optical lens |

Continual zoom step lens 1:6.5 |

||||

|

Magnification |

Optics magnification :0.7 ~ 4.5 x; Image magnification: 24 ~ 158 x |

||||

|

Software |

SBK - special CNC automatic measurement software |

||||

|

Power |

220 V/ 50 Hz /3 A |

||||

|

Working environment |

Temperature: 20 ℃±2 ℃, temperature change <2 ℃/ hr, Humidity:30 ~ 80% |

||||

|

Special table for machine |

built-in switching power supply, controller, motor drive, power supply control switch, indicator light, abrupt stop switch, move the wheel |

||||

|

Warranty period |

12 months |

||||

Main features:

♦ High performance Panasonic servo motor motion device to ensure high mute, high precision and high repeatability under high speed operation

♦ TPI precision screw, which makes the measurement positioning accuracy accurate and reliable, and the positioning accuracy can reach 0.001mm

♦ The column and base are made of high-precision granite structure, which is stable and reliable.

♦ Equipped with SBK-CNC multi-function measurement software to increase the measurement speed by 2 times than the AC series automatic image measuring instrument.

♦ Imported German "RSF" 0.0005mm metal grating, measuring data more stable and high precision

♦ Measurement data can be imported into Word, Excel, AutoCAD, and report output functions, and easy to output test results.

♦ With automatic contour scanning, contour tracking, automatic product shape scanning and other functions.

♦ Three-axis adopts Taiwan Shangyin precision linear slide rail and TBI high-precision ball screw to ensure machine accuracy and service life.

♦ CNC high-definition automatic zoom navigation lens and 130W digital CCD.