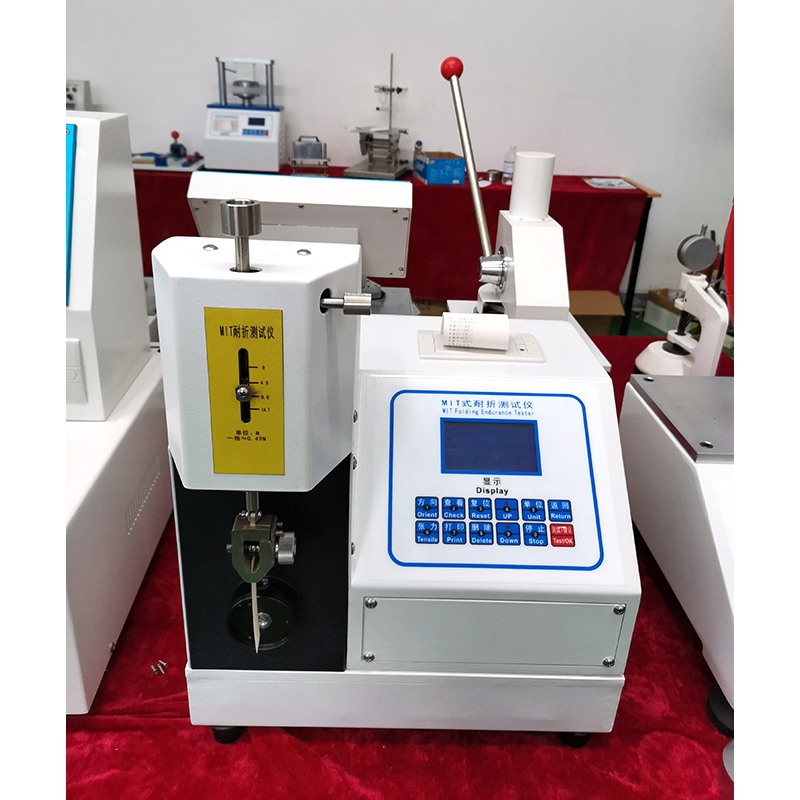

Overview:

This product is specially designed to test the folding strength of paper and paperboard. The test method is to fix the two ends of the test piece on the machine, the lower clamp is applied with the required load, so that the test piece is subjected to a certain tension, and the lower clamp is in the vertical state of the test piece. The sample was reciprocally bent on the left and right sides, and the bending angle was 135 degrees until the test piece was broken and automatically counted. Folding resistance refers to the logarithm of the number of double folds required for reciprocal folding to a fracture under standard conditions. The folding resistance is one of the basic mechanical properties of paper, which is used to indicate that the paper resists reciprocating folding. ability. The folding resistance of paper is the number of folds required to measure the paper after it has been stretched by a certain force, and then folded back and forth to break it. The number of folds is expressed in number of times. The unit is double-folded, and the vertical folding resistance is tested according to the longitudinal cutting test. The result of the transverse cutting test is the lateral folding resistance, and the general longitudinal folding resistance is higher than the transverse folding resistance, which is due to the arrangement of the fibers and the large bonding force of the longitudinal fibers. It is mainly used for flexing cardboard and circuit boards (commonly known as software circuit boards) for flexural testing; such as mobile phone, PDA, electronic dictionary, laptop computer and other electronic products FPC soft board flexural and flexural life testing test.

Standard:

APPI-T423PM, ASTM-D2176, JIS-P8115, ISO 5626: Determination of pleat resistance of paper GB/T 2679.5: Determination of folding resistance of paper and paperboard (MIT folding resistance method) QB/T 1049: Paper and cardboard Folding resistance meter

Technical characteristics:

1. Microcomputer control technology, open structure, simple and convenient operation, safe and reliable.

2. Automatic measurement, statistics, print test results, and has a data save function.

3. After the test is completed, it will automatically return to the zero function.

4. Optical mechatronics modern design concept, compact structure, beautiful appearance, easy maintenance.

Parameter:

|

Sample size |

15×(150~200)mm |

|

Load |

Weight 4.91N, 9.81N, 14.72N |

|

Folding angle |

135°±2° |

|

Folding speed |

175±10/min |

|

Folding head width |

19±1mm |

|

Spring tension |

4.9~14.7N, when adding 9.8N tension, the spring compresses at least 17mm |

|

The tension change caused by the eccentricity of the folding chuck is not more than 0.343N |

|

|

Folding mouth gap |

0.25mm/0.5mm/0.75mm/1.00mm (glass fiber materials and other materials can be customized) |

|

Standard weight |

4.9N,9.8N |

|

Counter |

0~999,999 |

|

Arc radius of the fold |

0.38±0.02mm |

|

HMI |

3.2 in 320*240 dot matrix liquid crystal display, display fold change times in real time |

|

Print out |

Modular integrated thermal printer |

|

Dimensions |

340mm×350mm×460mm |

|

Weight |

40kg |