Product introduction:

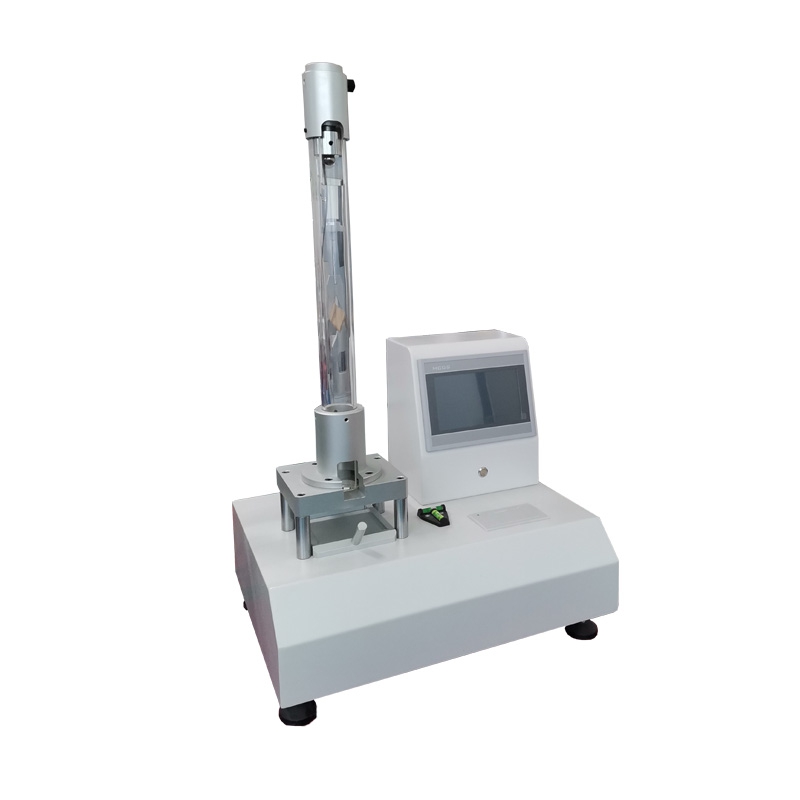

The Microcomputer Sponge Rebound Rate Tester is a cost-effective instrument designed to measure soft materials such as sponges, foams and rubber. The steel ball is mainly freely dropped on a flexible foam or other elastic material sample. The instrument for determining the rebound height is mainly used to determine the rebound resilience (rebound coefficient) in the polyurethane elastic material test item.

Implementation criteria:

GB/T6670-2008 design and manufacture, in line with ASTM American Standard D3574 and ISO8307 technical parameters

Technical parameter:

| Power supply voltage | 220V 50HZ |

| Instrument test resolution | 1/10000 seconds |

| Rebound coefficient measurement range | 25%-80% |

| Falling ball rebound rate accuracy | <1.5% |

| Steel ball drop distance | 460+0.5%mm (national standard) 500+0.5%mm (American standard) |

| Steel ball diameter | ¢16-0.05 mm |

| Automatic calculation of average rebound height | |

| Automatic calculation of average rebound rate configuration | |

Working principle:

Sponge, foam, rubber and other materials should be stored for at least 72 hours before testing. Before the test, the sample shall be conditioned at a temperature of 23 ± 2 ° C and a relative humidity of 45% - 50% for at least 16 hours, and then tested in the above environment.