Summary:

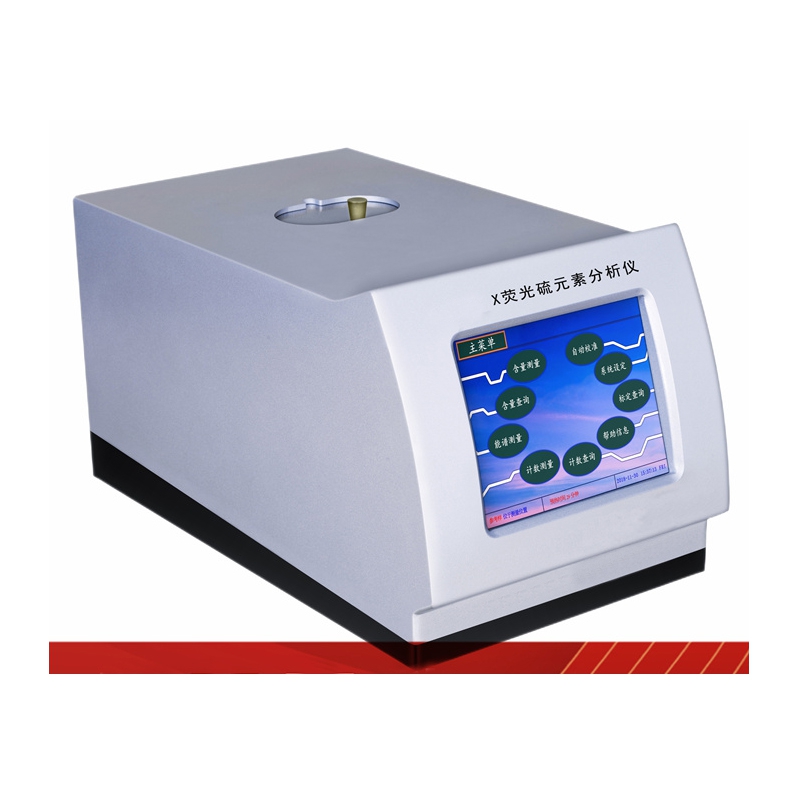

The applicable standards for X-ray fluorescence sulfur analyzer are GB/T 17040, GB/T 11140, and ASTM D 4294-03, which are developed and manufactured to meet the needs of sulfur content detection in oil products. It adopts the principle of energy dispersion and is designed with mechatronics integration and microcomputer analysis quick. Its repeatability and reproducibility provide important means for detecting sulfur content in crude oil or petrochemical production processes.

Application scope:

1. Measure the total sulfur mass percentage content of crude oil, petroleum, heavy oil, diesel, kerosene, gasoline, and naphtha

2. Measure the total sulfur content in coal chemical products, such as primary benzene

3. Measurement of total sulfur or sulfide content in other liquid samples

4. Determination of total sulfur or SO3 content in fine powder samples, such as petroleum coke, modified asphalt, and other carbon elements

Product configuration:

|

Sulfur measurement range |

0.0017%~100% |

|

Repeatability (r) |

<0.4347 X0.6446 (X=average of two repeated test results) |

|

Reproducibility (R) |

<1.9182 X0.6446 (X=average of two single, independent test results) |

|

Sample size |

4ml~6ml |

|

Measurement time |

60~180 seconds, can be set arbitrarily |

|

Number of calibration curves |

The instrument can access 10 calibration curves |

|

Single sample automatic measurement, measurement repetition rate |

1, 2, 3, 5, 10 can be set arbitrarily, and the average value and standard deviation are given at the end of the measurement |

|

Environmental temperature |

10 ℃~30 ℃ |

|

Relative humidity |

≤ 85%(30 ℃) |

|

Power supply |

AC100-220V/50Hz, rated power: 50W |

|

Dimensions |

460*260*260mm |

|

weight |

11kg |

Feature:

1. Intelligent electromechanical integrated microcomputer design, 8-inch wide angle capacitive touch screen (1024 * 768) display;

2. Using ultra-thin beryllium window proportional counter tubes and original imported color filters;

3. Wide range of detection varieties, wide detection range, fast analysis speed (only 1 minute at the fastest), and low consumption of standard samples;

4. The instrument has an automatic diagnostic function, which monitors the working status and electrical parameters of the instrument;

5. Disposable Mylar membrane sample cup to avoid cross contamination; The production of sample cups is convenient and fast;

6. The sample stage has precise positioning, making it very convenient to place samples and replace leak proof oil films, while avoiding the possibility of contamination of the detection system;

7. The instrument has a large storage capacity, with 4096 content analysis results and 8192 count measurement data, 16 instrument calibration result data.

8. After the content detection is completed, the result data is automatically sent to the upper computer through the serial port;

9. Silent thermal printer automatically prints detection results;

10. The instrument automatically selects the working curve without user intervention;

11. Users can choose the measurement unit, ppm or (m/m)%;

12. Safe radiation protection measures, no ionizing radiation harm to individuals or groups, users do not need to apply for radiation permits