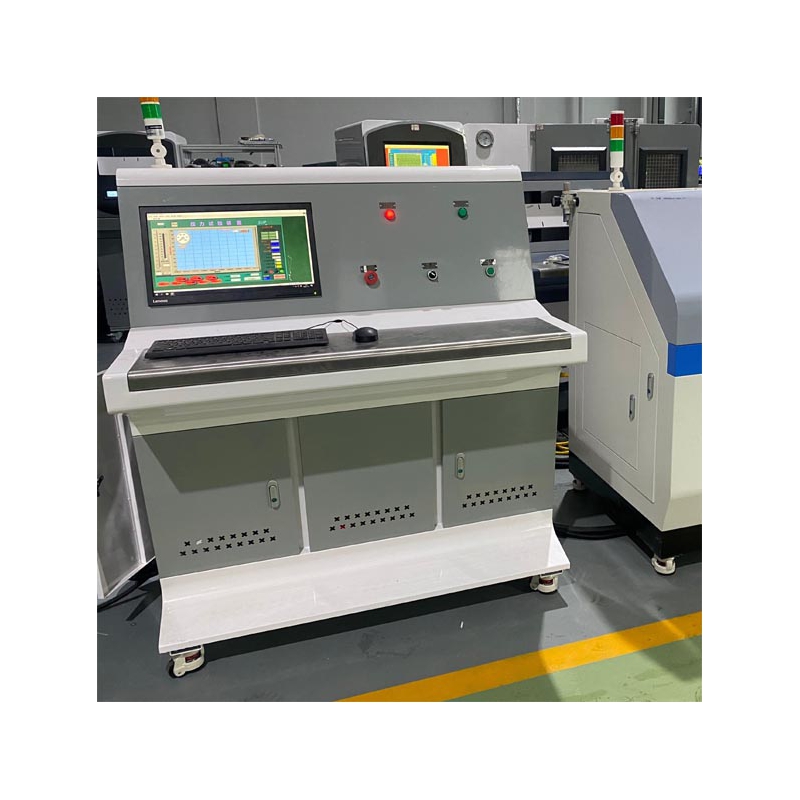

Hydraulic Cylinder Bursting Test Machine

Overview:

The piping system adopts non-welded connection. The test fluid system and the drive fluid system are separated, the test medium is diversified, the equipment is controlled by computer, and it is based on the national standard GBT 15385 gas cylinder water pressure bursting test method.

Feature:

1.The core booster equipment uses Simint booster pump, which can easily realize the output pressure can be adjusted and controllable.

2.Advanced technology, reasonable structure design. It has the characteristics of small size, light weight and beautiful appearance.

3.Aall pressure parts are made of international well-known brand standard parts, without any welding connection, easy to disassemble, high safety factor, long life, easy to maintain.

4.Driving pressure range: 0.1-0.8Mpa; And the output pressure is proportional to the driving pressure.

5. Air consumption: 0.1m3/min

6.Pressure test range: 100Mpa.

7.The computer can control the boost pressure, real-time display of the pressure curve, after the test can print the test report.

8.Can achieve phased test pressure.

9. The software can set different step-up pressures in stages.

10. The test time of the staged pressure holding process can be counted down automatically, and the time is over to remind.

11. It can automatically stop pressurization by stages to a certain pressure.

12.After the test can print the test report in Chinese and English, you can save excel table data.

13. Support data playback.

14.Can automatically draw time - pressure, time - water intake curve

16. The explosion-proof cylinder is equipped with a safety lock, which cannot be tested when opened.

The typical pressure test process is as follows

1, constant speed boost - blasting;

2, constant speed boost - pressure - blasting;

3, constant speed boost - pressure - pressure relief;

4, constant speed boost - maintain pressure - constant speed boost - maintain pressure - until blasting (increasing pressure boost);

Parameter:

|

Principle |

According to the different pressure of the sample, the high pressure output by the booster pump is carried out to check the sample. |

|

|

Other |

Test pressure |

100MPa |

|

Pressure control accuracy |

The upper limit of the test pressure value is + 2%, the lower limit is -1% |

|

|

Test medium |

Water |

|

|

Pressure control system |

Computer control |

|

|

Ambient temperature |

Normal temperature |

|

|

Sample quantity |

1 station control test pressure and test time |

|

|

Sample mounting mode |

Screw thread |

|

|

Structural composition |

Circulation system, pressure control system, workpiece mounting device, manual control |

|

|

Boost flow |

Low pressure 2.5L/min, high pressure 0.5L/min |

|

|

Driving pressure |

0.2-0.8MPa |

|

|

Drive flow |

0.1 cubic meters per minute |

|

|

Time display |

Computer display |

|

|

Pressure curve display |

The data acquisition software is displayed in real time and can be placed in miniature |

|

|

Print report |

After the test, you can print the test report and save the test data |

|

|

Test data preservation |

It can save reports and excel test tables, and the data collected can be saved every time |

|

|

Display accuracy |

0.01MPa |

|

|

Control accuracy |

The upper limit of the test pressure value is + 2%, the lower limit is -1% |

|

|

Balance accuracy |

1g |

|

|

Sensor accuracy |

0.5%FS |

|