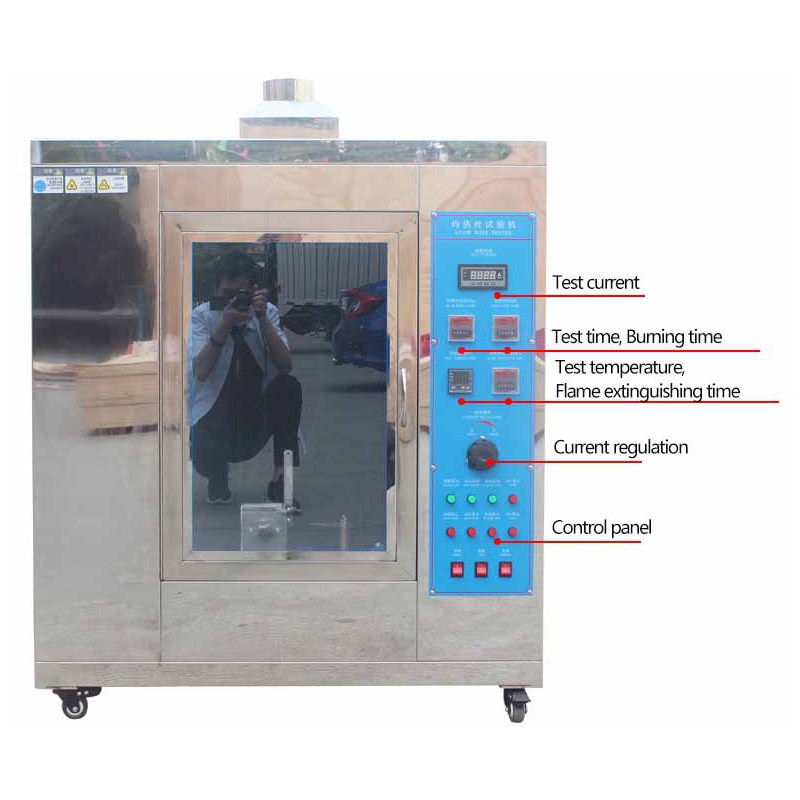

Application:

The device is designed and manufactured according to the requirements of "glow-wire test method" in IEC60695-2-10: 2000, GB / T5169.10-2006, GB / T5169.13-2006 and GB4706.1 standards. It is suitable for electrician and electronics Fire hazard testing of products, appliances and their materials to simulate thermal stress caused by heat sources or ignition sources such as burning elements or overload resistances in a short period of time.

Technical Parameters:

| Working power | AC220V, 50Hz, ≤ 500W |

| Heating temperature | 500-1000 °C ≤ continuous adjustable range, temperature measurement accuracy of ± 10 °C |

| Burning time | 0.1-999.9s, ± 0.1S (adjustable time range) |

| The light-off time | 0.1-999.9s, automatic recording |

| The flame extinguished time | 0.1-999.9s, automatic recording |

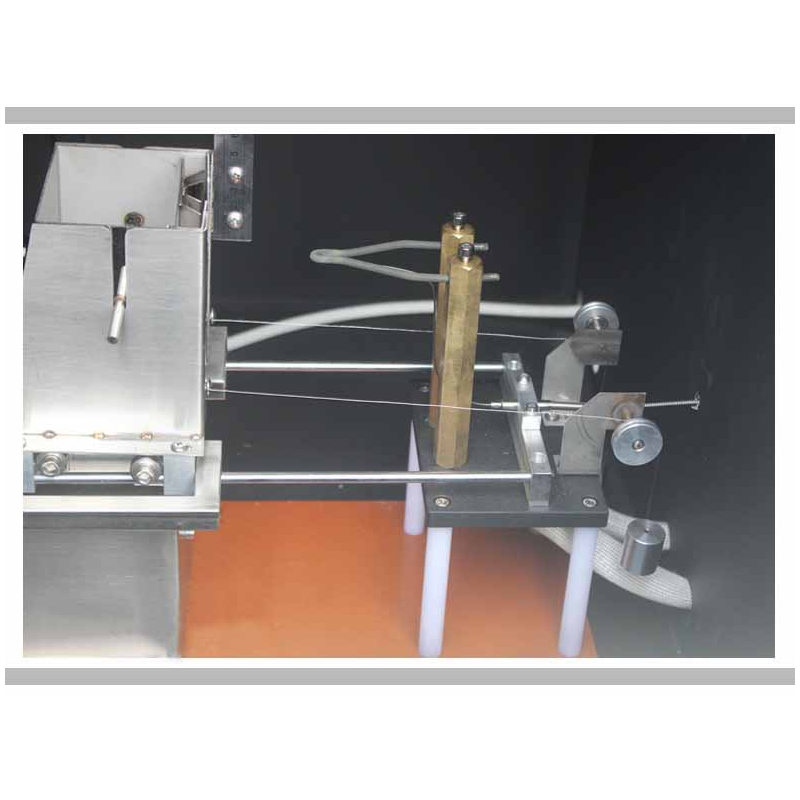

| Hot wire pressure on the sample | 1 ± 0.2N (with weight), the pressure limiting depth of 7mm |

| Glow wire | φ4 nickel (80%) chromium (20%) made in accordance with the provisions of the size |

| Thermocouple | φ0.5 armored nickel-chromium / nickel aluminum wire, K indexing, the United Kingdom imports, to the ground insulation |

| Automatically from | the sample reaches the specified burning time, automatically from glowing wire |

| The combustion chamber | w*d*h 1100*550*1150mm (internal volume of more than 0.5 cubic meters, can be made for 0.75 cubic meters, 1 cubic); box wall black, illumination less than 20lx, Stainless steel production, combustion chamber and control box in the same box |

|

Glow wire to the pine board adjustable distance, with a docking tray, five silk paper, pine board one; Second, the timer and temperature controller using imported instruments (Autonics) |

|

Accurate measurement of the main parts:

1.Relay: Omron

2. Digital instruments: South Korea autonics (Autonics) display.

3 circuit breaker: Schneider

4. Buttons, switches, lights: Shanghai.

5. Box: made of 1.2 thick 304 stainless steel, the surface paint.

Suitable for: