Specifications:

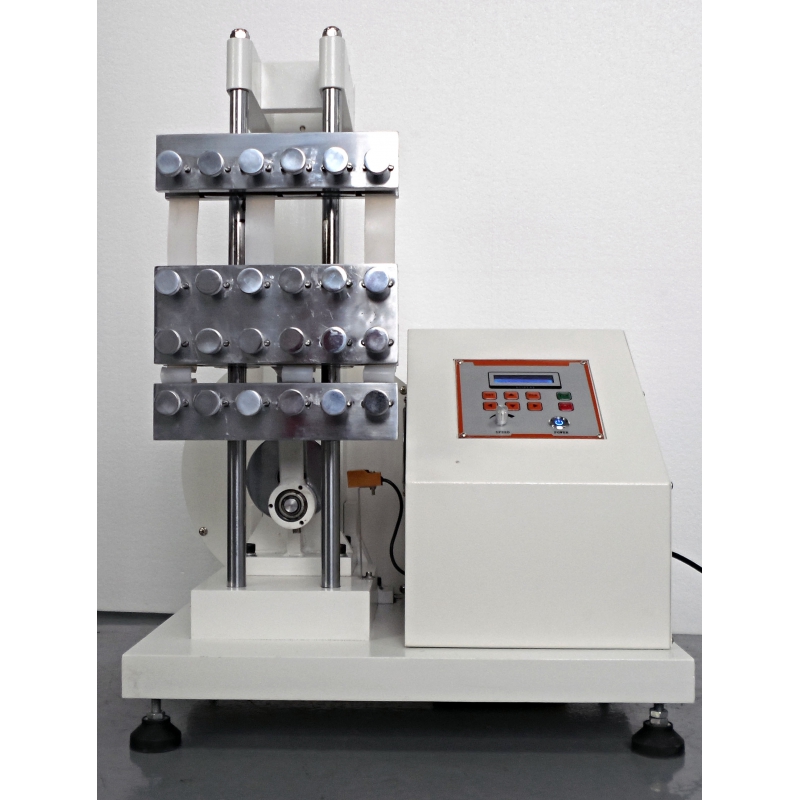

| Items | Rubber Dynamic Bending Fatigue Test Equipment |

|

Test Station |

6 or Custom |

|

Specimen |

154×25±1×6.3±0.15mm |

|

Grips Max. Space |

75 +1 mm |

|

Reciprocating trip |

57 +0.5 mm |

|

Test Speed |

300±10 times/min |

|

Count |

LCD display, 0~999,999 |

|

Power |

220V, 50/60Hz |

Summary:

Rubber Dynamic Bending Fatigue Test Equipment features variable speeds for testing fatigue, breakage or crack growth in rubber, plastics, leather, fibre optics and exotic composites. These models are designed with simplistic and durability in mind. The rigidity of the tester yields accurate results.

Rubber Dynamic Bending Fatigue Test Equipment are essential for helping companies assess the durability of rubber components such as vulcanized rubber. Specimens of rubber are subjected to repeat flexing over a specified period of time so that the levels of flex cracking and crack growth can be determined.

Features:

1. Production additives settings and adjustments

2. Inspection of quality products

3. In-process checks to ensure on-spec product for converting operation

4. Quality-control reporting

5. Widely used in the automotive, rubber and textile industry

Applicable Standards:

ISO 132 --Rubber, vulcanized or thermoplastic -- Determination of flex cracking and crack growth (De Mattia)

ASTM D430 --Standard Test Methods for Rubber Deterioration-Dynamic Fatigue

ASTM D813 --Standard Test Method for Rubber Deterioration-Crack Growth

BS 903 --Methods of testing vulcanized rubber

JIS K6301 --Physical testing methods for vulcanized rubber