Product Features:

The multifunctional washing and drying integrated machine improves the shortcomings of traditional horizontal cleaning equipment used in enterprises, such as low efficiency, long time, and water outflow.

The multifunctional washing and drying integrated machine has high efficiency and is completed by high-pressure cleaning, water throwing, and drying in one go, without the need for manual waiting time. The equipment adopts a PLC programming control system to automatically stop at time, and only workers need to load and unload materials. It is widely used in various industries and can also be used in the field of food cleaning, product surface grinding, and product surface spraying.

Machine parameter:

|

water consumption |

About 10L(Depending on the product) |

|

Air flow range |

0~200m3/h, Accuracy: Level 5 |

|

Rated volume |

100L |

|

Cleaning cylinder aperture |

5mm |

|

Applicable products |

Less than 3*3*3cm |

|

Rated voltage |

380V |

|

Max. rated power |

11.5W |

|

Overall dimensions |

110×150×160cm |

|

Net weight |

400kg |

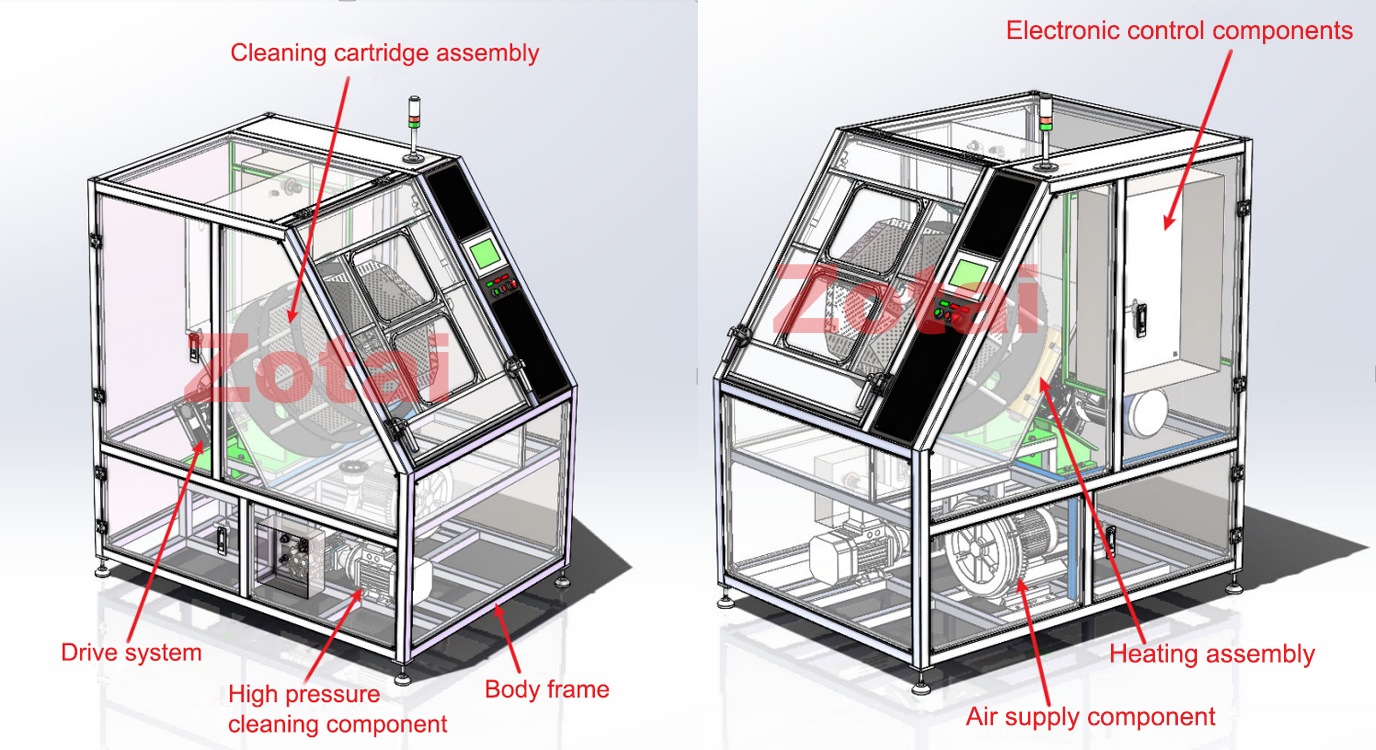

Equipment composition:

This equipment mainly consists of high-pressure cleaning components, air supply components, heating components, frame and transmission system, electronic control components, cleaning fluid spraying components, silicone oil incremental spraying components, ultraviolet sterilization and disinfection components (customizable according to customer needs), cleaning cylinder components (304 stainless steel), and other parts

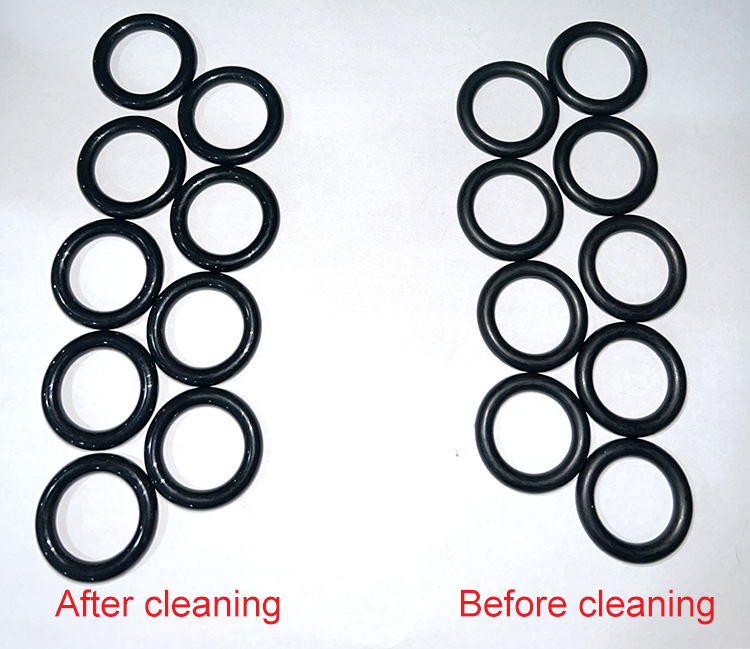

Applicable products:

This device can be used to clean products made of granular rubber, plastic, and other materials within a size of approximately 3*3*3cm, as shown in the sample image. The cleaning inner cylinder adopts a detachable method, with a default drum size of 5mm holes. Users can customize a dedicated drum according to the product size.

Operating instructions:

1. Place the product in the cleaning cabinet, close the cabin door, and lock the handle;

2. Set the cleaning solution spraying time, high-pressure water cleaning time, inner cylinder rotation speed, air drying time, and inner cylinder rotation speed on the touch screen, and then press the "Start" button;

3. Wait for the equipment to automatically clean and dry, the green light will light up, open the cabin door, take out the product, and complete one cleaning;

4. During the cleaning process, if you need to stop, please press the "Stop" button before opening the cabin door. In case of emergency, please immediately press the "Emergency Stop" button;

5. Due to differences in product types and capacities, there may be differences in the time and inner cylinder speed of each step. Please ensure that the settings are correct to achieve the best usage effect.