Key Specification:

|

Range |

200N.mm |

500N.mm |

1000N.mm |

2.000N.m |

5.000N.m |

10.000N.m |

20.00N.m |

|

Division value |

0.2N.mm |

0.5N.mm |

1N.mm |

0.002N.m |

0.005N.m |

0.010N.m |

0.02N.m |

|

Unit |

N.mm,gf.cm,ozf.in |

N.m,kgf.cm,lbf.in |

|||||

|

Accuracy |

±1% |

||||||

|

Rotation range |

-3000.0~+3000.0° |

||||||

|

Angle division value |

0.1° |

||||||

|

Loading method |

manual |

||||||

|

Rotation diameter of test piece |

Φ100mm |

||||||

|

Specimen height |

80mm(Special requirements can be customized) |

||||||

|

power supply |

AC 220V 50HZ |

||||||

|

Dimensions |

450*300*320 |

||||||

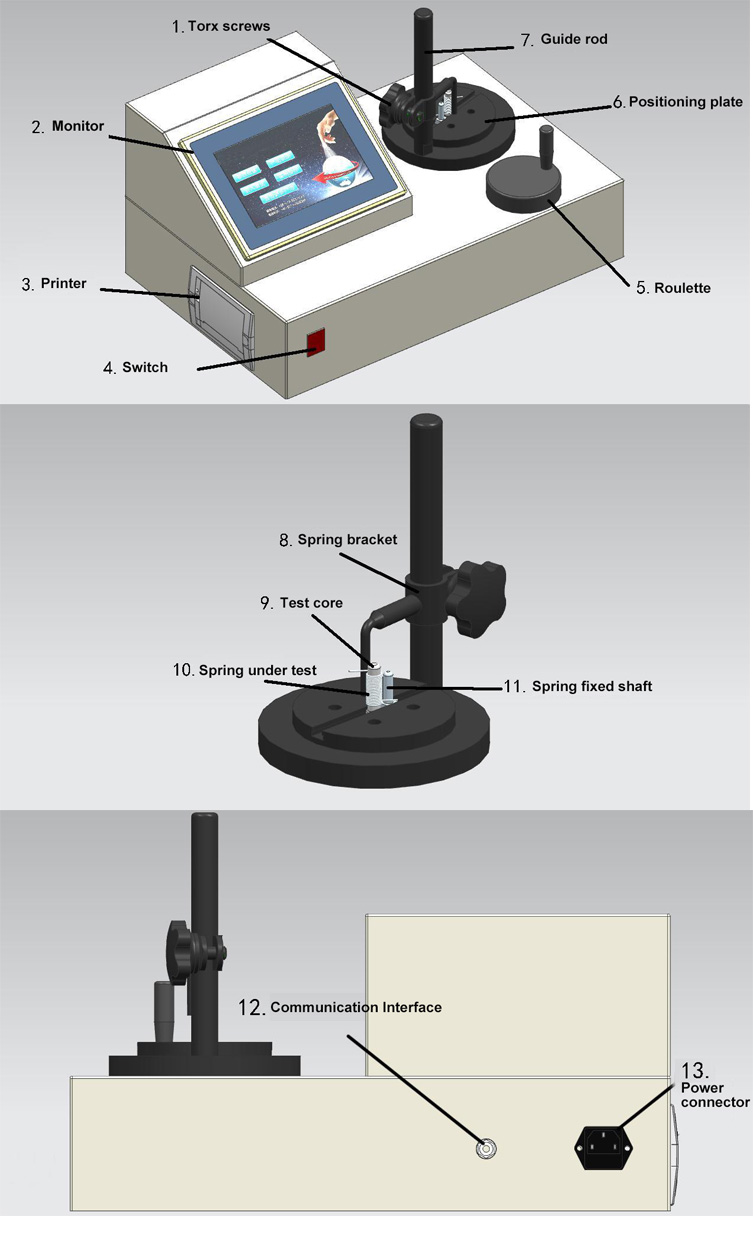

This series of vertical manual spring torsion test equipment is suitable for testing the torsion angle and torque of torsion springs, scroll springs, elastic elements and friction mechanisms. The torsion test of parts and components can also be carried out by adding corresponding accessories. This machine refers to "JB/T 9370-1999" and "JJG 269-2006" torsion testing machine standards and material testing methods. It can test and provide data according to national standards and international standards such as ISO, JIS, ASTM, DIN, etc.

It is an ideal testing equipment for industrial and mining enterprises, technical supervision, commodity inspection and arbitration, scientific research institutes, universities, quality inspection units and other departments.

Features:

1. High precision, high resolution, high stability

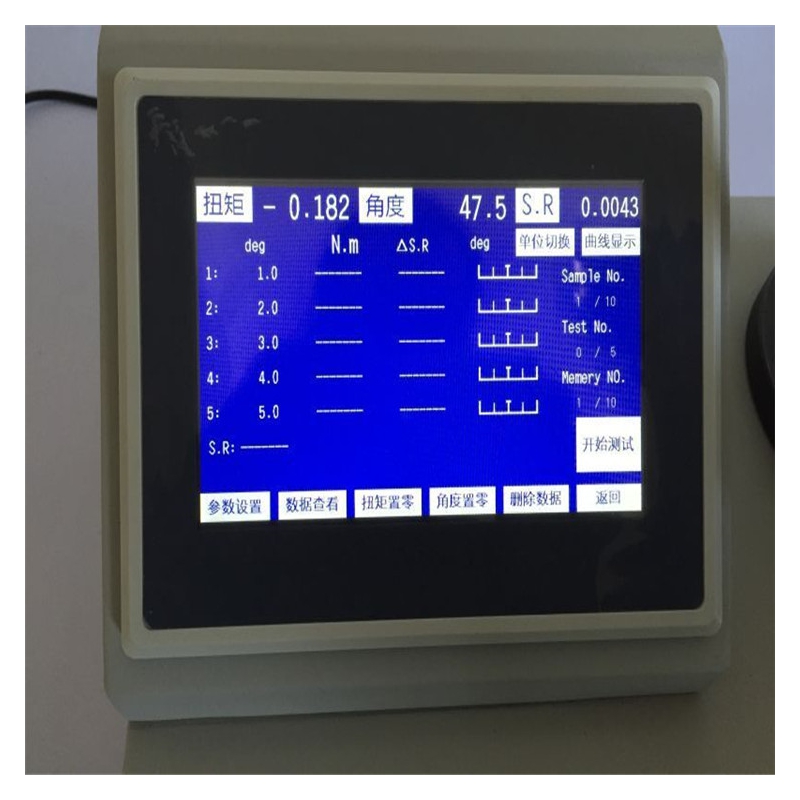

2. Large 7-inch touch LCD screen, easy to use man-machine interface

3. Test direction display (clockwise -, counterclockwise +)

4. Three units (N.mm, gf.cm, ozf.in)/(N.m, kgf.cm, lbf.in) are automatically interchange

5. 5 test points can be customized, and the allowable torque value of the corresponding point can be set. The test interface can display the deviation degree of the test point torque value in real time

6. 10 different test items can be customized, and different test points can be set separately. After the first save, the test can be started by directly loading in the future without setting again

7. The test interface can display real-time stiffness, segment stiffness, and overall stiffness

8. You can view the saved 10 sets of test data, and automatically calculate the stiffness of the data, the degree of error deviation, and make statistics, display the pass rate, stiffness, the maximum, minimum, and average values, the torque values of each set point, and view the displayed content can be printed out by printer

9. The gravity acceleration value can be set

10. USB online communication, can save test items, real-time data, and export excel files to facilitate later data processing

Working conditions:

1. Power condition: ~220V 50Hz. The input voltage error range is ±10%, and the instrument should

be properly grounded to prevent damage caused by leakage of the instrument

2. Operating environment conditions: Ambient temperature: 5℃-40℃ Relative humidity ≤85%RH No vibration source

3. The machine should be placed on a level (approximate area: 45cm*30cm or more) and has a certain strength for installation and positioning.

caveat

3.1. When moving, both sides of the base must be lifted, and the housing must not be moved directly.

3.2. Before operation, you should be familiar with the operation steps and methods, and be used by someone