Introduction:

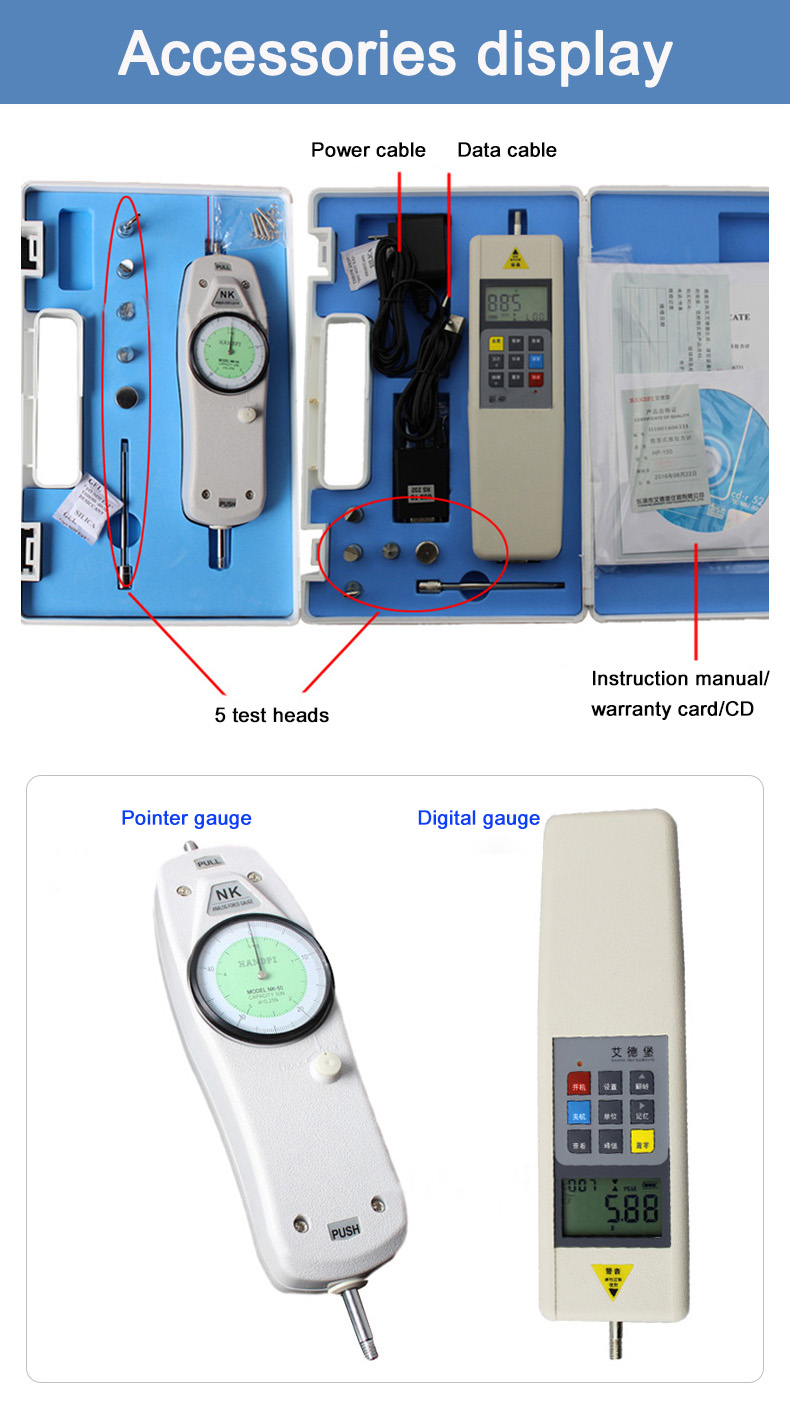

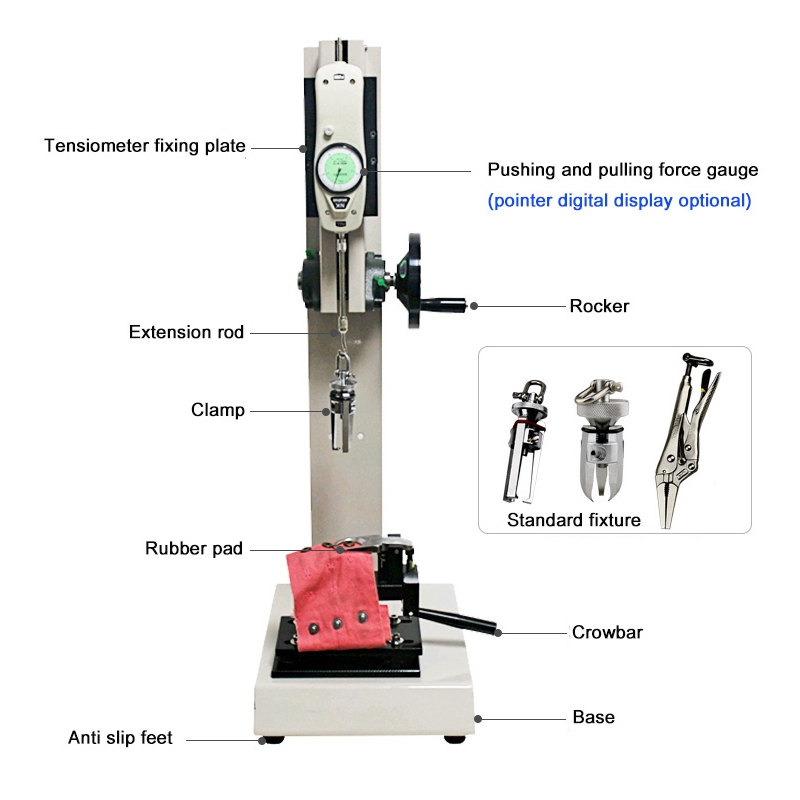

The button tester can be equipped with NK and HP series push and pull gauges and specialized fixtures, specifically designed to measure the button‘s closing force or breaking force when detached from clothing. Testing the fixing strength of buttons, buttons, and other components is a very important standard, especially in the design and manufacturing of infant and children‘s clothing. The measurement of the use of a certain force on button fixing decorative components needs to be recorded through a force instrument.

Function:

Button testing can ensure that buttons, buttons, and fasteners can be properly fixed to ready-made clothing or toys, preventing buttons from detaching and posing a risk of swallowing by infants.

Applicable products:

All buttons, buttons and fixed decorations on ready-made clothes and toys (which can be fully placed into small object measuring devices) must be tested by a button tester.

Technical Parameter:

|

Load |

10N |

20N |

30N |

50N |

100N |

200N |

300N |

500N |

|

Load graduation value(pointer type) |

0.05N |

0.1N |

0.2N |

0.25N |

0.5N |

1.0N |

2.0N |

2.5N |

|

Load graduation value(Digital type) |

0.001N |

0.01N |

0.1N |

|||||

|

Error |

<±1% |

|||||||

|

Test itinerary |

180MM(Excluding fixture stroke) |

|||||||

|

Units |

N/kgf(Pointer type) N/lbf/kgf(Digital type) |

|||||||

|

Fixture |

3 types of standard fixtures (optional with other fixtures or customized fixtures) |

|||||||

|

External dimensions |

260mmx360mmx700mm |

|||||||

|

Machine weight |

About 30KG |

|||||||