Summary:

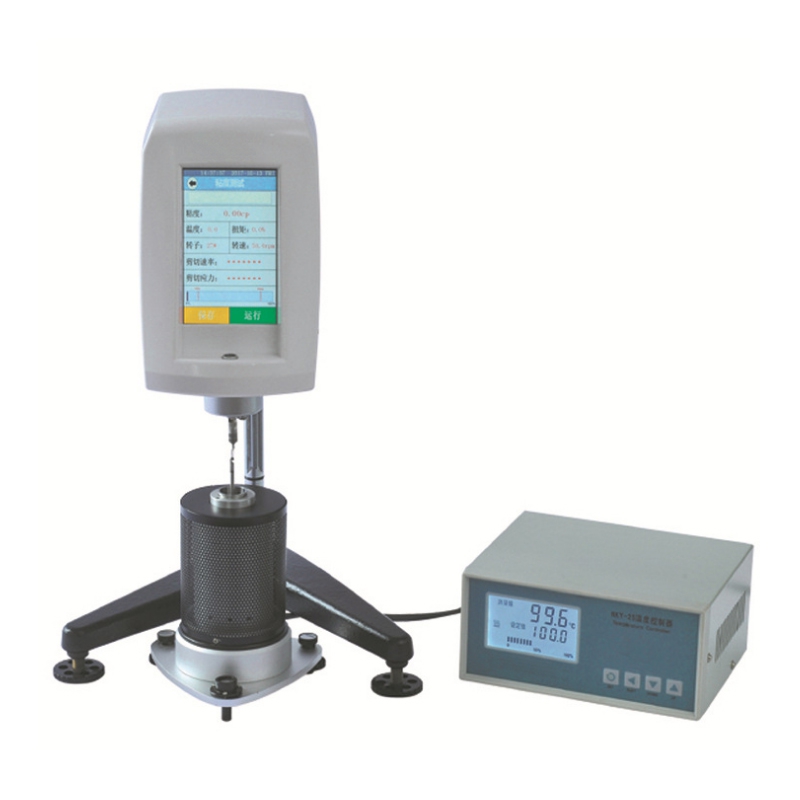

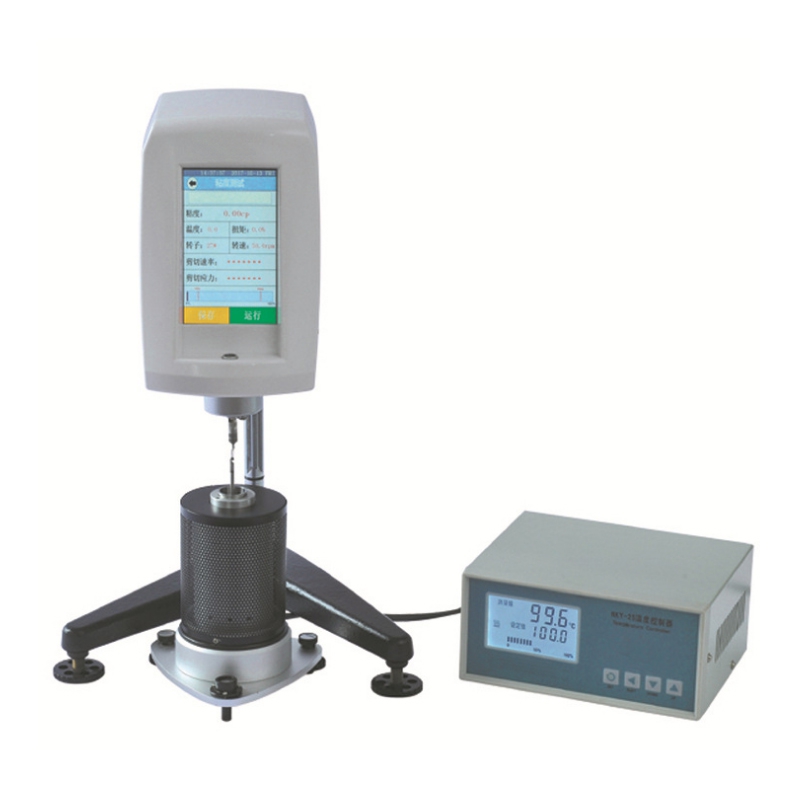

Using a coaxial center structure, using a small sample adapter, each measurement requires a very small sample size, temperature control quickly and accurately. It has many measuring parameters, rich display content, convenient operation, intuitive reading, high measuring precision, stable rotational speed, strong anti-interference performance, wide working voltage and so on.

Main features:

1. adopts ARM technology, built-in Linux system. Operation interface is simple and clear, through the creation of testing procedures and data analysis, fast and convenient viscosity testing;;

2. Accurate viscosity measurement: each measuring range is automatically calibrated by computer with high precision and small error;

3. Display rich: in addition to viscosity (dynamic viscosity and kinematic viscosity), there are temperature, shear rate, shear stress, measured value as a percentage of the full range value (graphic display), range overflow alarm, automatic scanning, maximum measurement range under the current rotor speed combination, date, time, etc. The kinematic viscosity can be displayed under the known density to meet the different measurement requirements of users;

4. Fully functional: can be timed measurement, self-built 30 groups of testing procedures, access to 30 groups of measurement data, real-time display viscosity Curves, printed data, curves, etc.;

5. Stepless speed regulation:

RV1T series:0.3-100 rpm, a total of 998 rotational speeds

RV2T Series:0.1-200 rpm,2000 rpm

6. Shows the curve of shear rate to viscosity: can set the range of shear rate, real-time display on the computer; can also show the curve of time to viscosity

7. Operating System in English and Chinese

Measurable in a very large range from 50 to 80 million MPA.S, samples that can meet various high viscosity high temperature melts (e.g. hot melt adhesive, asphalt, plastics, etc.)

Optional ultra-low viscosity adapter (rotor 0) can also measure the viscosity of paraffin wax, polyethylene wax if molten sample.

Detailed technical parameters:

|

model |

RVDV-1T-H |

HADV-1T-H |

HBDV-1T-H |

|

Control/Display |

5-inch color touch screen |

||

|

speed(r/min) |

0.3~100, Stepless speed,998 speeds available |

||

|

measuring range (mPa.s) |

6.4 – 3.3M Rotor No.0:6.4-1K Rotor No.21:50-167K Rotor No.27:250-834K Rotor No.28:500-1.7M Rotor No.29:1K-3.3M |

12.8 – 6.6M Rotor No.0:12.8-1K Rotor No.21:100-333K Rotor No.27:500-1.7M Rotor No.28:1K-3.3M Rotor No.29:2K-6.6M |

51.2 – 26.6M Rotor No.0:51.2-2K Rotor No.21:400-1.3M Rotor No.27:2K-6.7M Rotor No.28:4K-13.3M Rotor No.29:8K-26.6M |

|

Rotor |

21,27,28,29(Standard) No.0 (Optional) |

||

|

Sample dosage |

Rotor No.0:21ml Rotor No.21: 7.8ml Rotor No.27: 11.3ml Rotor No.28: 12.6ml Rotor No.29: 11.5ml |

||

|

Measurement error |

±1% (Newtonian liquid) |

||

|

repetitive error |

±0.5% (Newtonian liquid) |

||

|

Show shear response/shear rate |

have |

||

|

Timing function |

have |

||

|

Real-time display Viscosity curve |

Time-viscosity curve Temperature-viscosity curve (optional temperature sensor) (Optional data processing software shows shear rate and viscosity curves) |

||

|

kinematic viscosity |

Density of samples to be entered |

||

|

measuring range |

Automatic display of selected combinations of rotor and rotation speed. Measurable viscosity range |

||

|

Self-built Measuring Procedures |

Save 30 groups (including rotor, speed, temperature, time, etc) |

||

|

Preservation of measurements |

Save 30 sets of data (including viscosity, temperature, rotor, speed, shear rate, shear stress, time, density, kinematic viscosity, etc) |

||

|

printer interface |

Print data, curves (need to buy printer) |

||

|

Computer output interface |

RS232 |

||

|

working power supply |

Viscometer mainframe: wide voltage operation (110 V/60 Hz or 220 V/50 Hz) Heating furnace and temperature control unit:220V50Hz |

||

|

outline dimension |

300*300*450(mm) |

||

|

model |

RVDV-2T-H |

HADV-2T-H |

HBDV-2T-H |

|

Control/Display |

5-inch color touch screen |

||

|

speed(r/min) |

0.1~200, Stepless speed2000 speeds available |

||

|

measuring range (mPa.s) |

3.2 – 10M Rotor No.0:3.2-1K Rotor No.21:50-500K Rotor No.27:125-2.5M Rotor No.28:250-5M Rotor No.29:500-10M |

6.4 – 20M Rotor No.0:6.4-1K Rotor No.21:50-1M Rotor No.27:250-5M Rotor No.28:500-10M Rotor No.29:1K-20M |

25.6 – 80M Rotor No.0:25.6-2K Rotor No.21:200-4M Rotor No.27:1K-20M Rotor No.28:2K-40M Rotor No.29:4K-80M |

|

Rotor |

21,27,28,29(Standard) No.0 (Optional) |

||

|

Sample dosage |

Rotor No.0:21ml Rotor No.21: 7.8ml Rotor No.27: 11.3ml Rotor No.28: 12.6ml Rotor No.29: 11.5ml |

||

|

Measurement error |

±1% (Newtonian liquid) |

||

|

repetitive error |

±0.5% (Newtonian liquid) |

||

|

Show shear response / shear rate |

have |

||

|

Timing function |

have |

||

|

Real-time display Viscosity curve |

Time-viscosity curve Temperature-viscosity curve (optional temperature sensor) (Optional data processing software shows shear rate and viscosity curves) |

||

|

kinematic viscosity |

Density of samples to be entered |

||

|

measuring range |

Automatic display of selected combinations of rotor and rotation speed. Measurable viscosity range |

||

|

Self-built Measuring Procedures |

Save 30 groups (including rotor, speed, temperature, time, etc) |

||

|

Preservation of measurements |

Save 30 sets of data (including viscosity, temperature, rotor, speed, shear rate, shear stress, time, density, kinematic viscosity, etc) |

||

|

printer interface |

Print data, curves (need to buy printer) |

||

|

Computer output interface |

RS232 |

||

|

working power supply |

Viscometer mainframe: wide voltage operation (110 V/60 Hz or 220 V/50 Hz) Heating furnace and temperature control unit:220V50Hz |

||

|

outline dimension |

300*300*450(mm) |

||