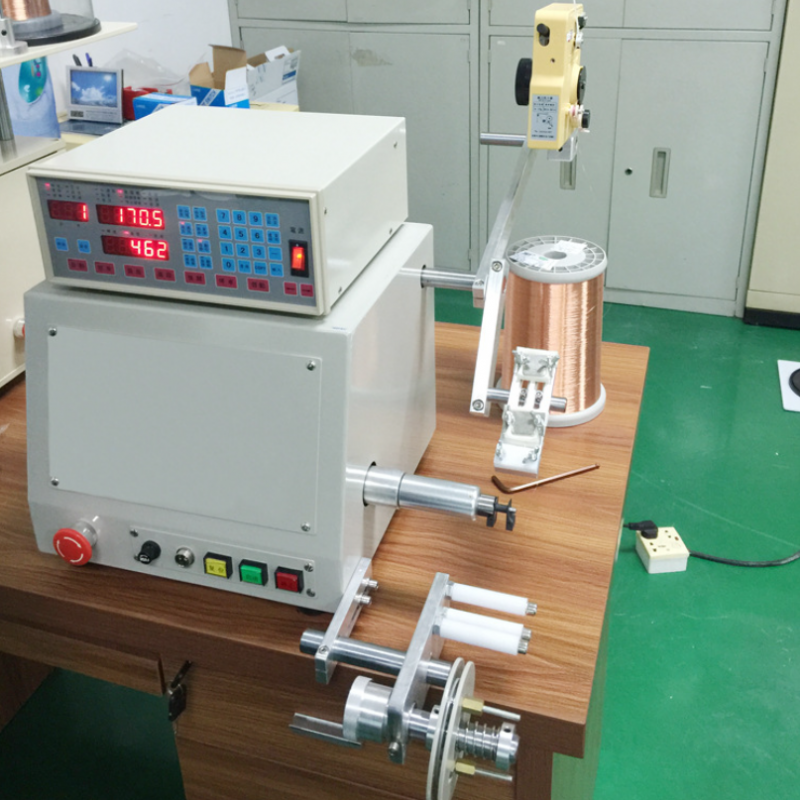

The main function of a winding machine is to wrap linear objects onto specific workpieces. They are commonly used for winding copper wires and are widely used in the manufacturing of electrical products, such as the winding of inductor coils. The winding machine is particularly important in transformer manufacturing, used for winding transformer coils to ensure compact structure, small volume, and high strength of the coils.

Purpose:

The application scope of CNC automatic winding machine products includes electronic toy coils, electronic clock coils, electronic gift coils, electronic lock induction coils, mobile phone vibration motor coils, animal ear tag induction coils, various voice coils for headphones and speakers, card reader coils, ID/IC automatic coin insertion device coils, camera coils, digital camera zoom coils, laser head coils, special magnetic head coils, wireless electromagnetic free mouse and mouse pad coils, automatic coin insertion device coils, hearing aid coils, attendance machine coils, solar rotary table coils, solar swing device coils, coin insertion detector coils, and brushless flat motor coils.

Technical parameters:

|

Wire diameter range |

0.03-0.8mm |

|

Cable spacing |

0-110mm |

|

Roll diameter |

150mm |

|

Memory groups |

1000 |

|

Spindle motor |

Brushless motor |

|

Power supply |

AC220V, frequency 50HZ |

|

Spindle forward and reverse speed |

6000RPM (optional) |

|

Net weight |

30KG |

|

Equipment dimensions |

430*330*420MM L*W*H(excluding cable rack) |

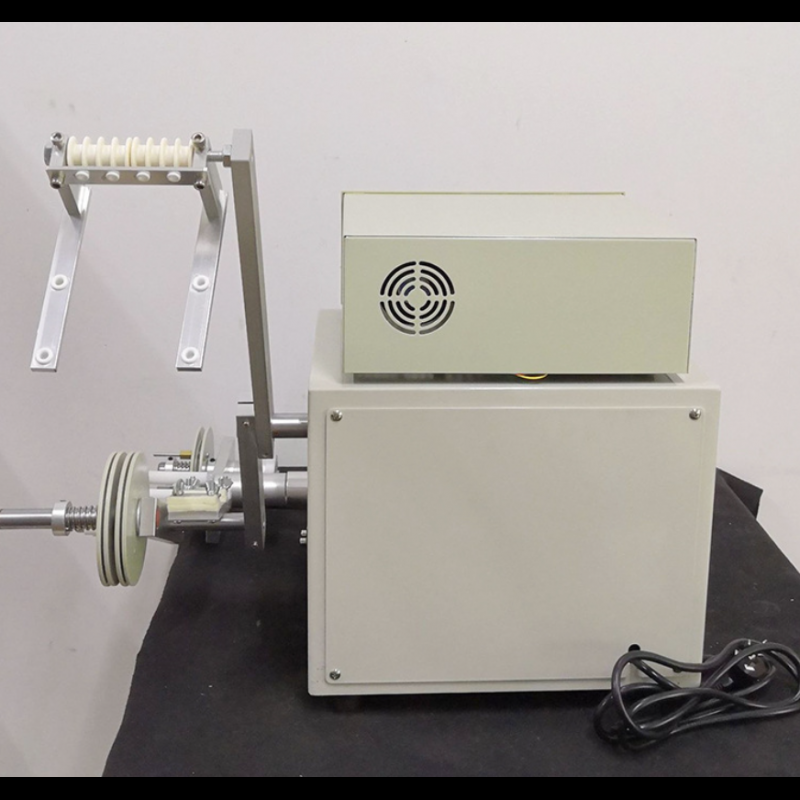

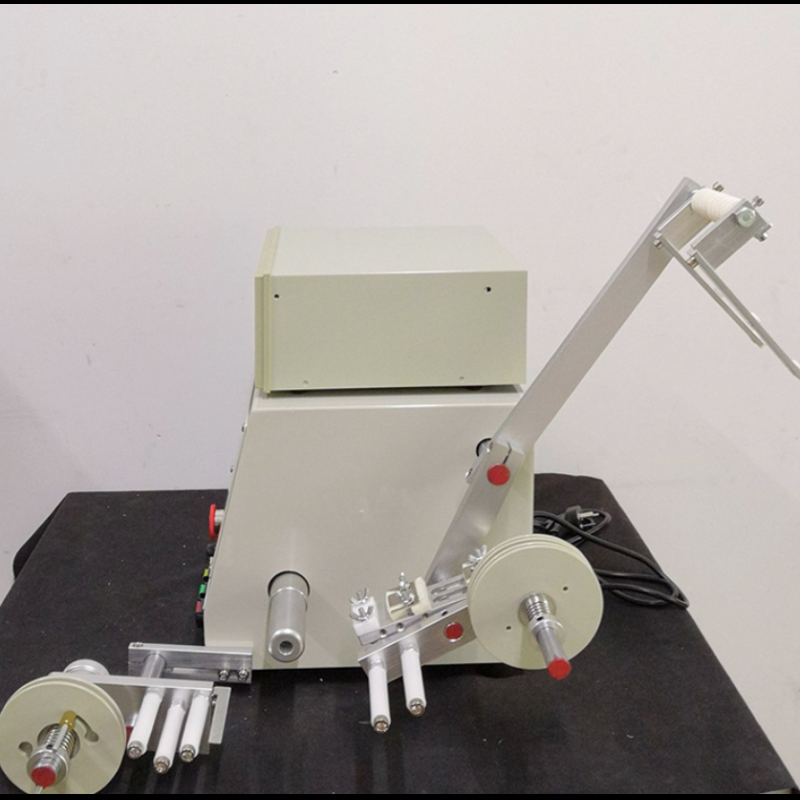

Feature description:

1. The main part is made of A3 material.

2. Other aluminum anodes undergo natural oxidation.

3. The controller, spindle motor, and cable motor adopt Shenzhen Leisai Technology.

4. The power circuit adopts an improved anti-interference circuit with stable performance.

5. The winding wire adopts a closed circuit with electronic speed feedback, with a constant speed that does not change with changes in mains power or load.

6. The cable shaft stepper motor is driven by constant current chopper, which is not easy to lose step.

7. The cable shaft is independently controlled by a microcomputer chip, which has better synchronization with the winding motor, fast cable speed, and high accuracy.

8. The starting position and width of the cable axis can be inputted in a teaching style during editing, and the current position of the cable axis can be displayed.

9. Every time the data is adjusted, the legality and accuracy of the data will be checked to protect the winding equipment and prevent winding errors.

10. The controller has integrated a three-phase DC brushless motor drive system, making installation and maintenance easier.

Purpose:

This instrument can select multiple test loads to meet the different testing requirements of wire and cable production enterprises and inspection departments for dynamic bending tests of flexible wires such as wires and cables.