Application area

The fully automatic coating machine is applied to various high and low frequency transformers, inductors, relays, filters, USB housings, charger housings, and other automatic coating/coating operations.

Technical parameter

|

Membrane range |

34~ 77mm, customizable |

|

Number of film turns |

1-9 turns, the number of turns can be set arbitrarily |

|

Two axle wheelbase |

The distance between the membrane fabric axis can be adjusted from 25~85mm (customizable) |

|

Voltage |

220V 50HZ |

|

Air pressure |

0.4-0.6MPA |

|

Power |

200W |

|

Production efficiency |

52-58 units/minute |

|

Machine dimensions |

1100*800*1200mm L*W*H |

|

Machine weight |

45KG |

Features

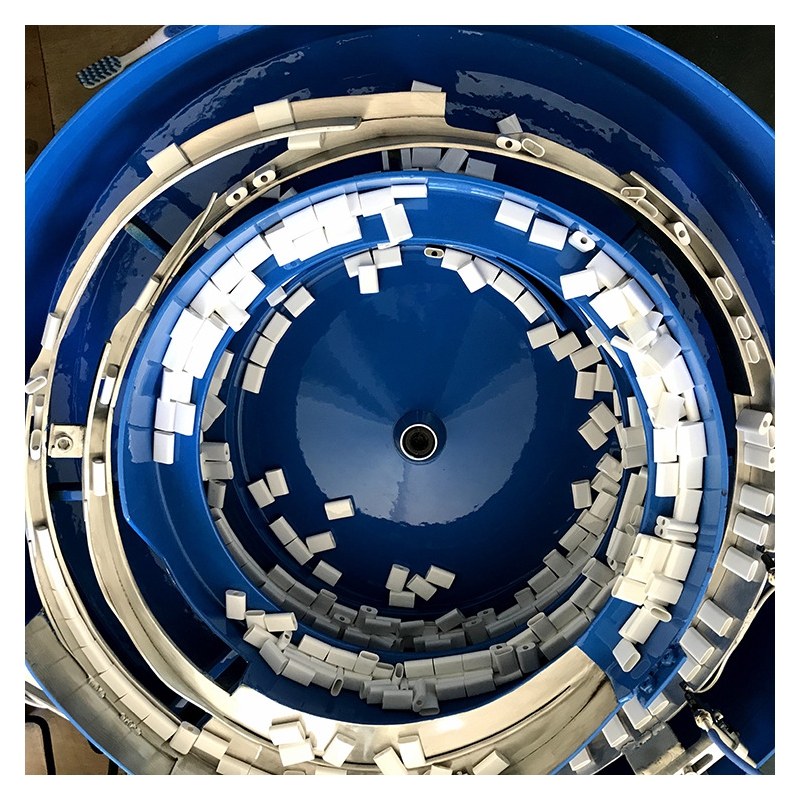

1. Operation steps: Put the material into the vibrating bucket - automatic feeding - automatic coating - automatic material return.

2. Function: Fully automatic application of protective film, no need for manual operation, convenient operation, with tape replacement reminder function

3. Different products can be replaced with different fixtures, and debugging is simple and fast, which can be completed in a short time. Any vertical or horizontal transformer, USB shell, or charger shell can be encapsulated with glue/film, and the variety of replacement is simple and fast, suitable for various operations;

4. The machine is controlled by a microcomputer program and driven by a reduction motor, ensuring the stability of the machine during operation;

5. Intelligent control system: dual display windows, A displays the required number of turns set, B displays the output of the work (can be cleared);

6. Tape error range: ± 0.2mm error;

7. Two winding tape heads can be replaced with each other to increase production;

8. The number of turns can be set, and the tape will be automatically cut and processed;

9. The tension of the wrapping tape can be adjusted, with a three-point and one line parallel feeding system. The wrapping tape is parallel and the closure is consistent.