Application:

Glow Wire Combustion Testing Equipment is used for electrician, its components, parts, solid electrical insulation materials or other solid combustible materials, in line with GB/T5169.10~13, IEC60695-2-1/0~2-1/3, GB2099 , VDE 0620, GB4706, UL817 test standards. Test method: Heat to the specified temperature with a standard resistance wire ring, and then make the glow wire in contact with the test sample under test conditions.

Testing method:

Use a standard resistance wire ring to heat up to the specified temperature, and then make the glow wire and the test sample contact plug and socket rubber and plastic products under the test conditions.

Specification:

Glow wire temperature: adjustable from room temperature to 1000°C;

Temperature thermocouples use nominally Ø0.5mm nickel-chromium and nickel-aluminum (K) armor filament thermocouples;

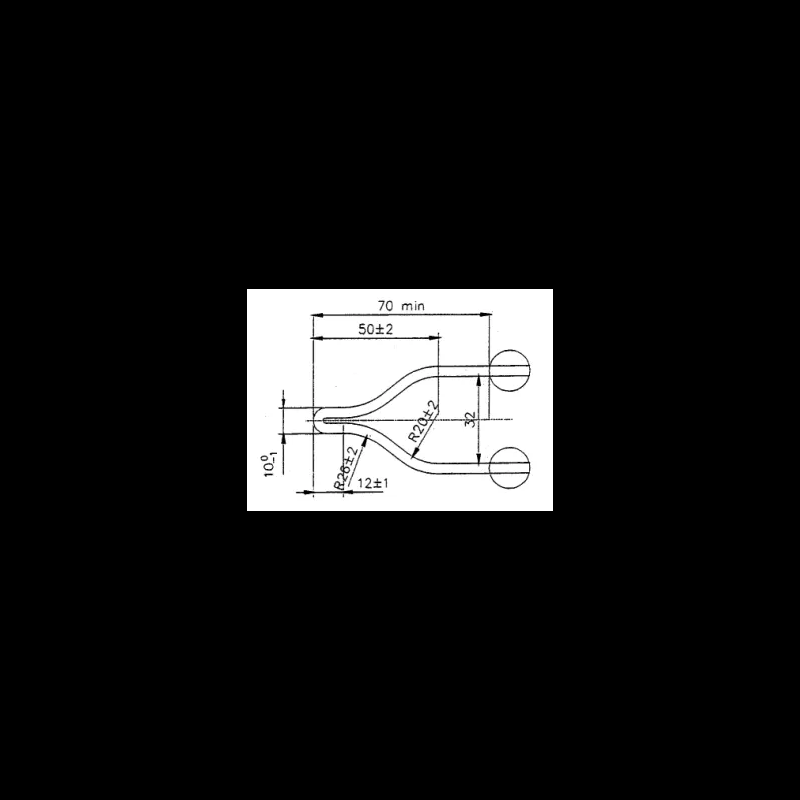

Glow wire is made of 4mm±0.04mm diameter nickel/chromium (80/20) wire to form a size ring.

Standard size please see the figure below:

1. Maintain a pressure of 1N ± 0.2N between the glow wire and the test sample, and limit the press-in depth to 7±0.5mm

2. The application time of the glow wire to the sample Ta(T1) is adjustable from 0 to 99 minutes and 99 seconds. Generally according to the standard requirements

3. Set for 30 seconds (setting timer "30S00"), and there is a timer for measuring the ignition duration Ti (T2) and the flame extinguishing time Te (T3).

| Dimensions (length*width*height) | 113cm*57cm*120cm(Paint) |

| 105cm*65cm*135cm(stainless steel) | |

| Studio volume | 0.5 cubic meters (other sizes can be customized) |

| Chassis material | paint / stainless steel |

| Power supply mode | single phase AC 220V / 50Hz |

| Total power | 500W |