Technical parameters:

|

1. Squeeze out some material |

|

|

Discharge port diameter |

Φ2.095±0.005mm |

|

Discharge port length |

8.000±0.025mm |

|

Loaded barrel diameter |

Φ9.550±0.025mm |

|

Loaded barrel length |

152±0.1mm |

|

Piston head diameter |

9.475±0.015mm |

|

Piston head length |

6.350±0.100mm |

|

2.Standard test load (eight grades) |

|

|

1grade |

0.325kg=(rod + weight + thermal units +1 No. tray body weight) |

|

2grade |

1.200 kg=(0.325+2 0.875 eight) |

|

3grade |

2.160 kg=(0.325+3 1.835 eight) |

|

4grade |

3.800 kg=(0.325+4 3.475 weight) |

|

5grade |

5.000 kg=(0.325+5 4.675 weight) |

|

6grade |

10.000kg=(0.325+5 4.675 weight+6 5.000 weight) |

|

7grade |

12.500kg=(0.325+5 4.675 weight+6 5.000+7 2.500 weight) |

|

8grade |

21.600 kg=(0.325+2 0.875+3 1.835+4 3.475+5 4.675+6 5.000+7 2.500+8 2.915 weight) |

|

Relative error of Load Test≤0.5% |

|

|

Test method |

Quality Act (MFR) |

|

Temperature range |

Room temperature——450℃ |

|

Temperature accuracy |

±0.2℃ |

|

Temperature resolution |

0.1℃ |

|

Timing range |

0.1——999 seconds |

|

Timing Accuracy |

0.1 seconds |

|

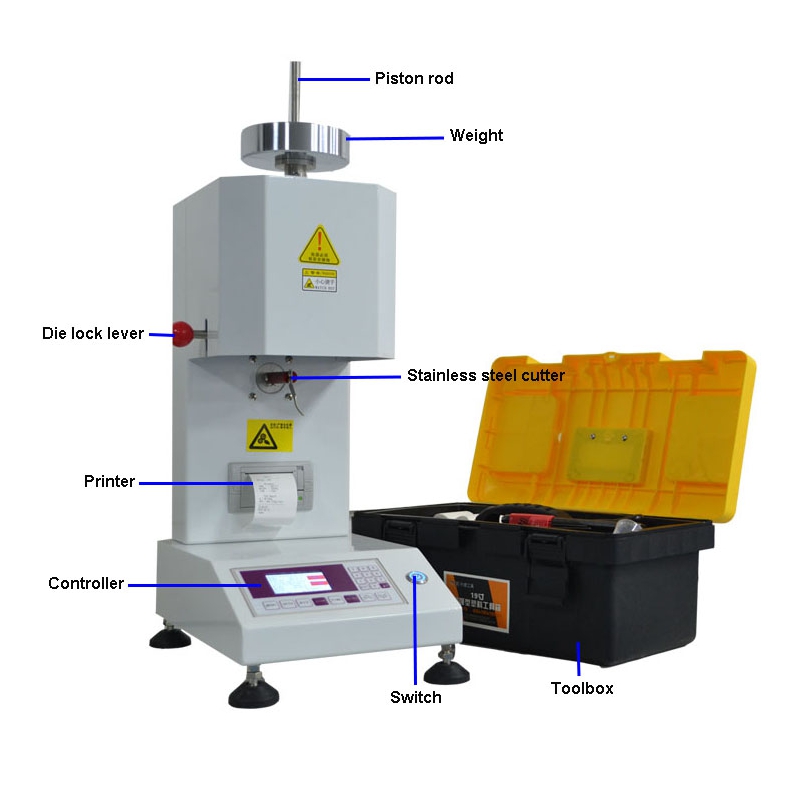

Material cutting method |

Automatic or manual way of cutting material |

|

Display |

LCS |

|

|

Equipped with a printer, can print test report |

|

Working conditions |

Ambient temperature10℃—40℃; Relative humidity30%—80% |

|

Dimensions |

250×350×510(L × W × H) |

Equipment Overview:

How it works:

Example:

By Industry:

Meet the criteria:

Click here for the video