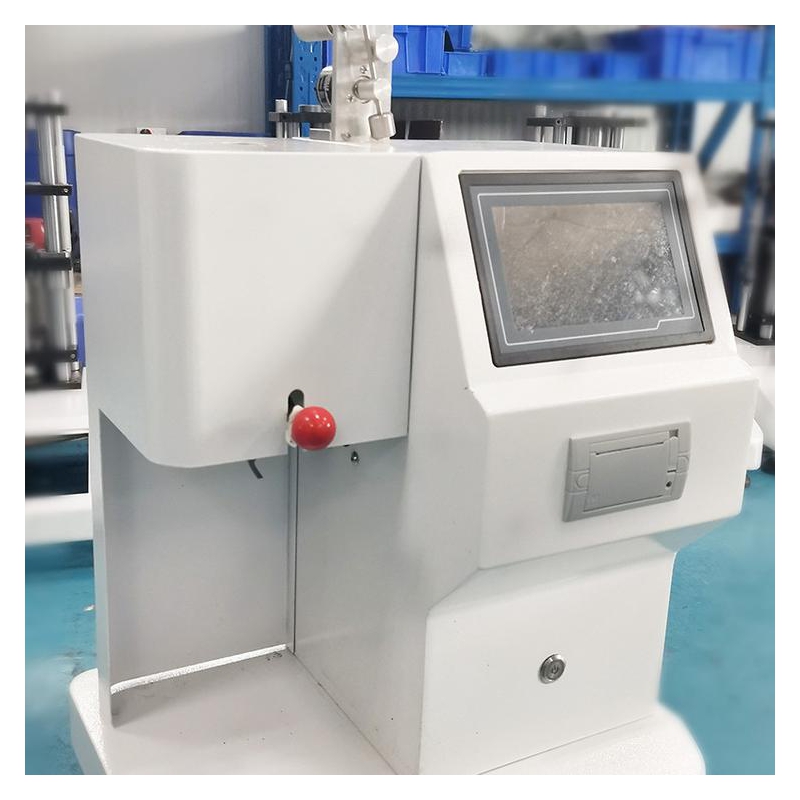

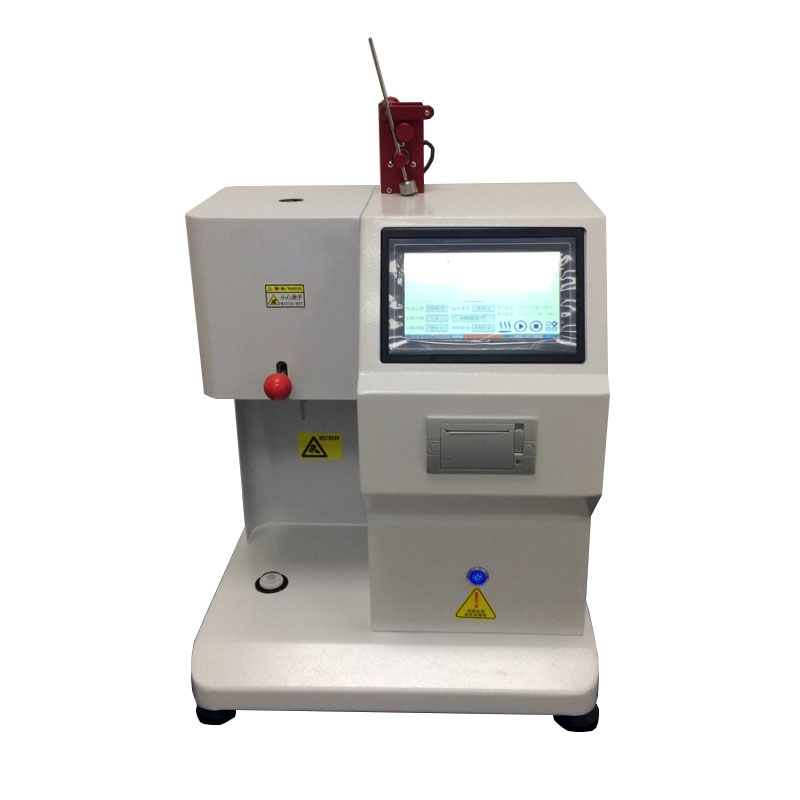

Plastic Rubber Melt Flow Index Tester

Specifications:

1. Extrusion section

| Die diameter | diameter 2.095±0.005mm |

| Die length | 8.000±0.025mm |

| Cylinder diameter | diameter 9.550±0.025mm |

| Cylinder length | 152±0.1 mm |

| Diameter of piston head | 9.475±0.015 mm |

| Length of piston head | 6.350±0.100mm |

2 . Standard test load (kg ,8 grades)

| 1st grade | 0.325kg = (piston stem +weight tray +heat insulation sheath +weight # 1) = 3.187N |

| 2nd grade | 1.200kg = (0.325+weight # 2 0.875) = 11.77N |

| 3rd grade | 2.160kg = (0.325+weight # 3 1.835) = 21.18N |

| 4th grade | 3.800kg = ((0.325+weight #4 3.475) =37.26N |

| 5th grade | 5.000kg = (0.325+weight #5 4.675) = 49.03N |

| 6th grade | 10.000kg = (0.325+weight #5 4.675+weight #6 5.000) =98.07N |

| 7th grade | 12.500kg = (0.325+ weight #5 4.675+weight #6 5.000+ weight #7 2.500) =122.58N |

| 8th grade | 21.600kg = (0.325+ weight #2 0.875+ weight #3 1.835+ weight #4 3.475+ weight #5 4.675+weight #6 5.000+ weight #7 2.500+weight #8 2.915) =211.82N |

| The test load relative error shall not be more than ±0.5% . | |

3.Temperature range : 50℃-450℃

4. Temperature constant accuracy : ±0.2℃

5. Resolution :0.1℃

6. Power :220V±10% 60H

Application:

China Factory Plastic Rubber Melt Flow Index Test Equipment of GB/T3682-2000, ASTM D3364 and ASTM D1238-98. And also, we design and manufacture the instrument after we made a reference of similar standards, such as JB/T5456 and ISO 1133.

It is used to determine the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics materials. It adopts auto sampling method and the cut samples are weighed up by balance when it is used to determine MFR. When it is used to determine MVR, it measures the time which the piston is used to move the specified distance first through the displacement transducer and auto timer system and calculates MVR according to the formula later. The final results of the two methods are all displayed on the machine’s LCD screen and printed and exported by computer. The instrument has high accuracy on data measurement with simple operation and stable capability. It is not only suitable for the tests of engineering plastics with higher melt temperature, such as PC, FI plastics, nylon, but also for the plastics with lower melt temperature, such as PE, PP, POM, PS, ABS resin and poly carbonic acid ester, etc. It has wide range of applications in some industries, such as plastic fabrication, plastic goods, petrochemical industry; collage and university and science and research institute and commodity inspection department.