Technical parameters:

|

Model |

ZT-1005 Laboratory Rubber Rotorless Rheometer |

|

Meet standard |

GB/T16584 / IS06502 |

|

Temperature tester |

Room temperature to 200°C |

|

Heating speed |

room temperature—200℃,about 10 min |

|

Temperature accuracy |

≤ ±0.1°C |

|

Temperature resolution |

0.1°C |

|

Torque range |

0-5N.M,0-10N.M,0-20N.M |

|

Torque resolution |

0.001NM |

|

Motor rotating speed |

100 times / min |

|

Rotor range |

Adopt 4 setting: 25, 50, 100, 200lbs per inch |

|

Die body pendulum |

1.7Hz±0.1Hz(100r/min) |

|

Rotor pendulum angle |

±0.5°, ±1°, ±3° |

|

Testing time setting |

3min--120min,choose freely |

|

Air compression |

0.5Mpa--0.65MPa |

|

Ambient temperature |

0-35°C |

|

Test result |

Printing:date,time,temperature,vulcanization curve,temperature curve,ML,MH,ts1,ts2,t10,t50,Vc1,Vc2. |

|

Consumption power |

800 w |

|

Dimension |

640mm×580mm×1300mm |

|

Power |

Single phase, 220V±10%, 50Hz |

|

Display |

Windows + software |

|

Weight |

About 260kg |

Applicable industry:

No Rotor Rubber Moving Die Rheometer widely used in rubber products industries.

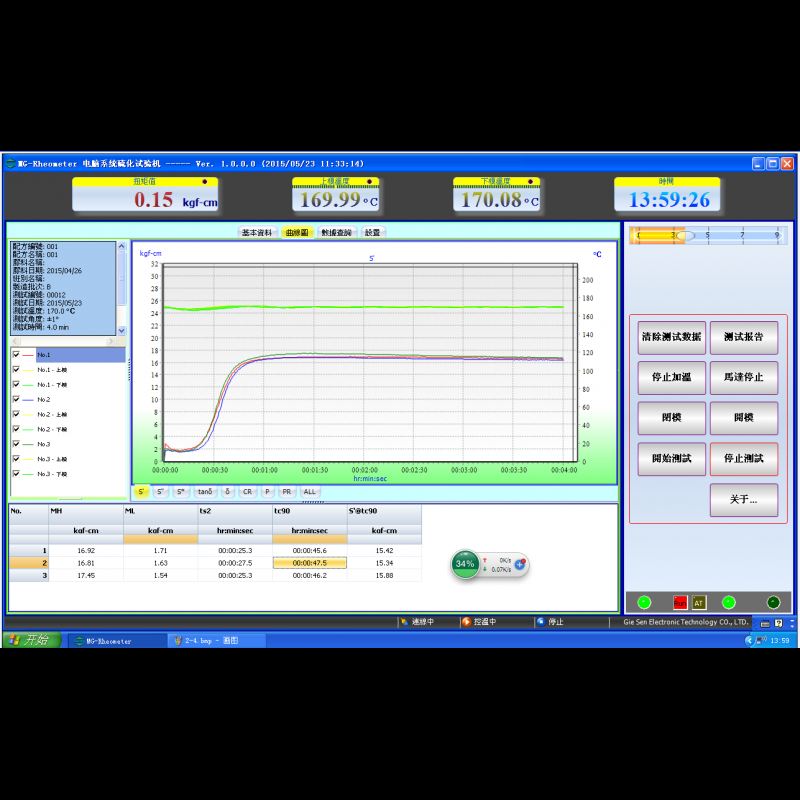

Software Introduction:

A. Testing standardization:GB/T16584, ISO6502:1991 and ASTMD5289-95.

B. Specimen information:set the material no,like “RBS6".User can set the title freely.

C. High quality function:You can modify the testing time when in operation.For example: When you set 20min to finish vulcanization,when in testing to 11min, you find the rubber material can finish vulcanization in 9min,and no need to test longer. You can modify the test time in software to 9min, the test will stop in 9min, and will draw integrity vulcanization curve and calculate the test data. If you test 18min,19min will finish, but it doesn‘t finish vulcanization, need to continue testing, or the testing data will be wrong. At this time, you can set the test time longer, modify 25min or more, Until the vulcanization finishing. It can time and rubber material.

D. Graph curve scale automatic optimization(Auto Scale), after testing, software can according to test data size to adjust Y scale, according to 0—5 Mv 0—10Mv 0-20Mv, making testing curve more beautiful, for different material, you can also compare the

data in software.

Main functions:

Non-curing equipment used monolithic rotor control, which include: host, temperature measurement, temperature control, data acquisition and processing, sensors and electrical chains and other components. These measurements, temperature control circuit consists of a temperature control device, platinum resistance, heater composition, capable of automatic tracking power and ambient temperature changes, automatically correct PID parameters to achieve fast and accurate temperature control purposes. Data acquisition system and mechanical linkage to complete the rubber

vulcanization process of force torch signal automatic detection, automatic real-time display of temperature and settings. After curing, automatic processing, automatic calculation, print vulcanization curve and process parameters. Show curing time, curing power Ju, also has a variety of audible alert.

non-rotor curing equipment controlled by computer, the computer setting the parameters of the direct control of test parameters Rheometer. Display real-vulcanization curve and temperature curve, store test results, different adjustable comparison of test results and in a different color.

Features:

1. This instrument is really confined mold cavity, and the United States Alpha (formerly Monsanto) has done. Repeatability, and test data comparable with the Alpha. At the international leading position in the same industry.

2,.The instrument development platform based on large databases, temperature control devices using the software to directly control and collection and processing. Instrument to overcome the general curing temperature of the shortcomings of using temperature controller (accuracy poor). The technical leadership of international new trend.

3. This instrument has statistics, analysis, storage and comparison functions. Humanized design, easy to operate

4. Using imported high-precision sensors