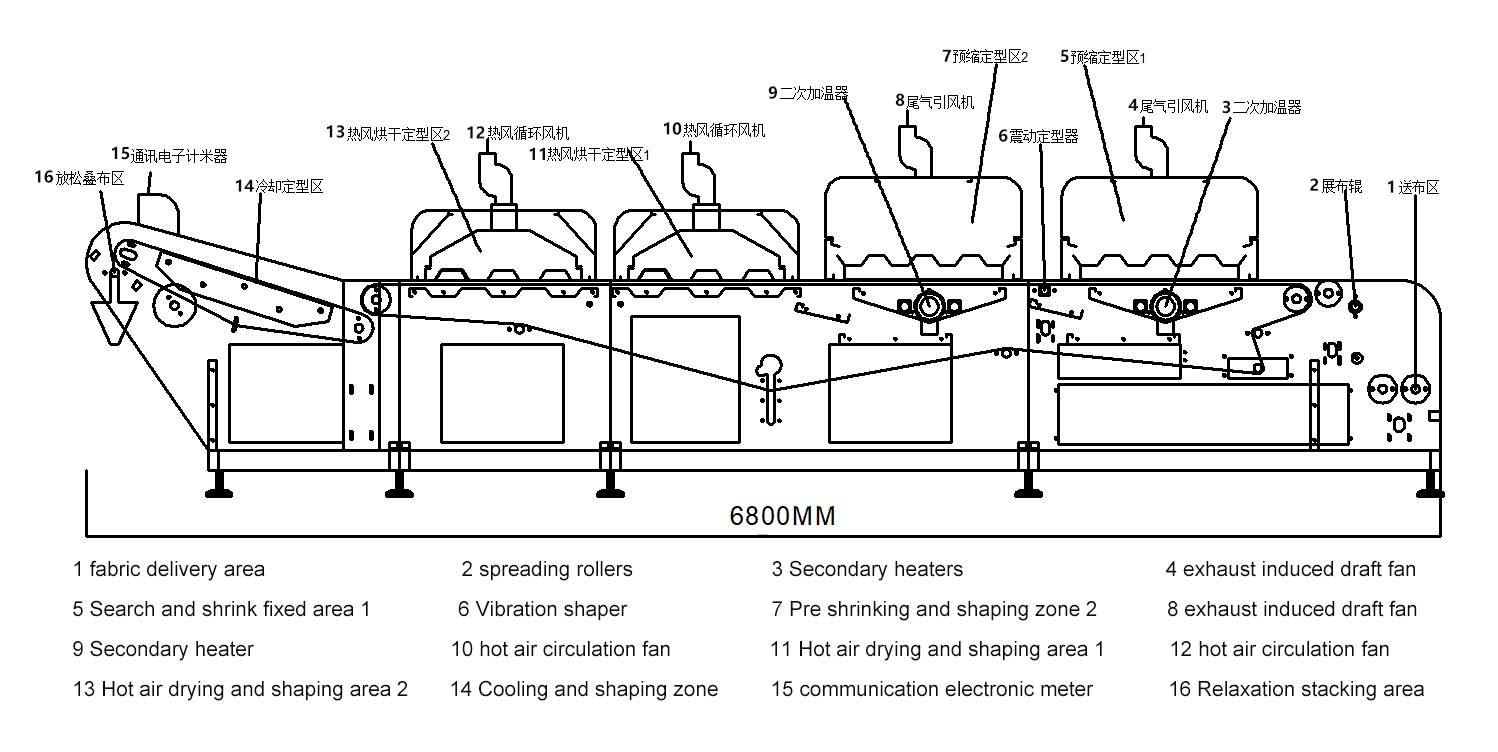

Machine configuration and features:

(1) 2 steam boxes+2 drying boxes+1 air-cooled area.

(2) Dual mesh belt operation saves steam, avoids hot and cold alternation, and waste of heat energy. Imported Kevlar conveyor belts are used in the steam and drying areas, while Teflon mesh belts are used in the air-cooled areas.

(3) The mesh belt is equipped with an infrared automatic correction device to protect it from damage and extend its service life.

(4) Using PLC programming control system, temperature, speed, and pressure are all displayed on the screen, and there will also be fault prompts, such as mesh belt deviation and emergency stop.

(5) The entire box and drying box are made of aluminum plates as the bottom plate and drip layer, and the two steam boxes are heated with mica heating plates.

(6) Two hot air drying zones are equipped with secondary heating devices to dry the steam box and drying box without dripping water. The steam temperature can be adjusted according to the fabric requirements, ranging from 125 ° C to 230 ° C, with fast heating

(7) Cooling device: Two steam boxes adopt a strong suction cooling system, which can completely cool and shape the fabric

(8) Ventilation hood device: absorbs residual steam from the humidification area, making the air in the workplace fresh

(9) Equipped with an electronic counter (with communication function, can be connected to a computer, import data and print QR codes),

(10) Shake fabric device: It can shake off residual water vapor on the mesh belt, avoiding dripping onto light colored fabrics, causing fabric pollution and damage, effectively repairing pinholes, sand holes, and diagonal lines.

(11) Three frequency converters control, protecting the motor from overload and overvoltage, variable frequency speed regulation, 0 to 60 meters per minute.

(12) Automatic fabric feeding device: ensures a certain sag between the fabric and the conveyor belt, allowing the fabric to be conveyed in a tension free state, preventing fabric elongation and deformation

(13) Comb and pull the edge rolling fabric screw device to avoid fabric wrinkling.

(14) Infrared electronic eye sensing, no fabric shutdown, automatic shutdown when no fabric is fed in.

(15) Unloading device: The fabric is folded into a piece of cloth through a swinging frame, or rolled neatly by a roller.

Parameters:

|

Usage width |

2200mm |

|

Steam consumption |

150kg/H |

|

Maximum roll fabric diameter |

50CM |

|

Drying temperature |

125°C-230°C adjustable |

|

Voltage |

380V/50Hz |

|

Processing speed |

0-60m/min adjustable |

|

Steam pressure |

0-0.7/MPa |

|

Body size |

6800 * 2700 * 1850mm |

|

Weight |

2350kg |

|

Power |

36KW |